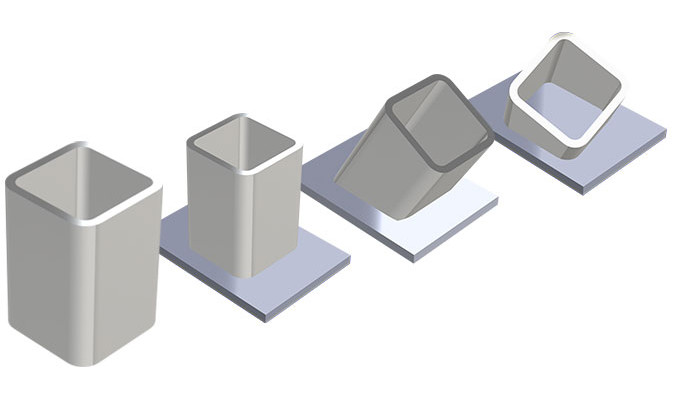

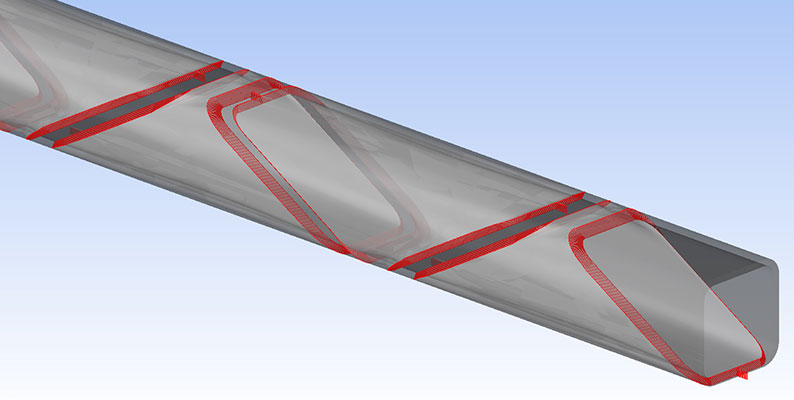

Chamfer Profiling Shapes are applied for plate connections or to connect box section ends. Sophisticated weld preparations is available to reduce your welding costs.

Features

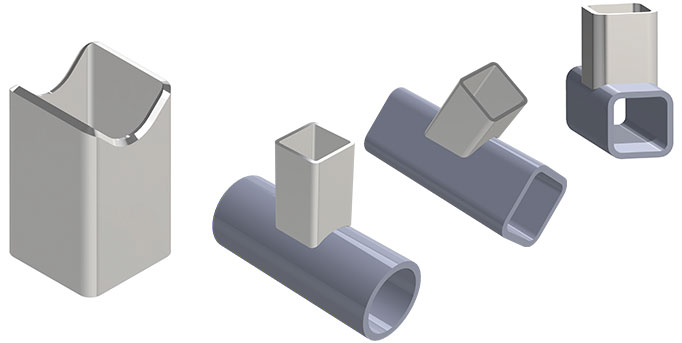

Saddle Profiling Shapes are applied to connect one or multiple colliding box sections with an intersecting pipe. It is also possible to connect a box section to a pipe. Sophisticated weld preparations are available to save welding costs.

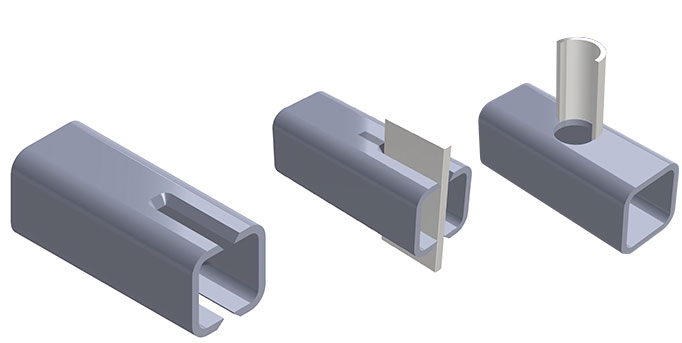

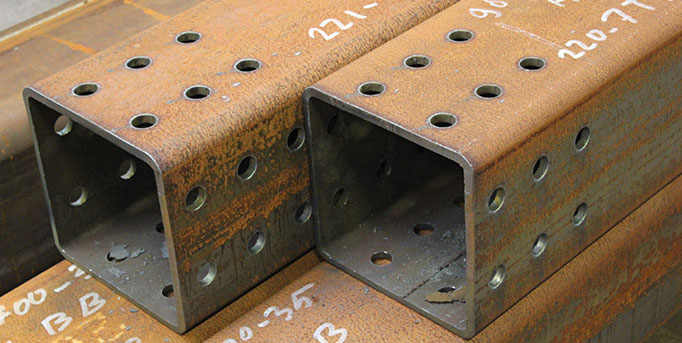

Slot and Hole Profiling are applied to fit gusset plates for structural steel or to create bolt holes.

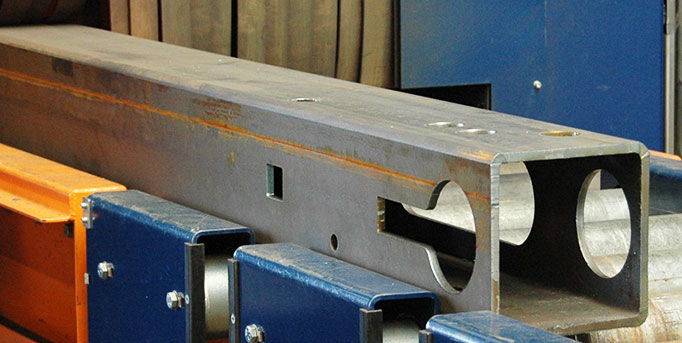

Do you need extraordinary shapes from your material. We have the solution. Please contact us for more information.

- Efficient Weld Preparation

- No Need for Drilling of Holes

- Reduce the Welding Volume on the Radius

- Easy Part Positioning

- Quality Certifications

- Advice on Design & Detailing

Reduce costs by minimizing your welding volume

Once cut by us your parts are ready for fast and easy fitting and welding. We do this by profiling a weld preparation for one or a combination of weld types to achieve an easy to fit and weld connection and a minimum of welding volume. Also considering shrinkage and root opening.

Receive your box sections ready for fast and easy assembling

We can cut the holes, needed for forming bolted connections, on your box sections instead of drilling them.

Reduce the welding volume on the radius for your box sections significantly

3D Profiling is not limited to straight (saw) cuts. This allows for exactly fitting of the contour of a box section including the radius on the edges. The combination of a perfect shape and advanced weld preparation reduces significantly your welding costs.

The extra step to further reduce your fitting costs

Having reference-lines and footprint-marking on both the main member and the branch member guarantees a quick and precise fit-up for saddle connections.

Stop worrying about standardized quality certifications

We are certified for ISO 9001, Lloyd’s 3.1 & 3.2 and Declaration of conformity NEN 1090.

Get an expert advice on detailing your weld-preps

We have the technology and knowledge to modify welding details to improve weldability and reduce welding volume. Of course all within the Welding Procedure Specification (WPS).

- Packing Services

- Track and Trace Parts

- A Minimum of Material Waste

- Lead time

- Packing and Transportation

Receive your parts neat & tidy

As an optional service, we can pack your box sections after being cut (e.g. bundling).

HGG is approved by Lloyd’s Register to remark materials and transfer heat numbers by EN 10204:2004 (3.1.B and 3.1.C). Nesting list and re-stamping certificate are available on request to improve quality and minimize manual efforts.

We make the most out of the material you send to us

HGG’s software calculates the most efficient nesting of parts. In many cases the parts will be positioned and rotated automatically into the raw material for achieving a minimum of scrap length.

We help to reduce your total processing time!

The perfect weldpreparation reduces your fitting and welding time. And with 6 cutting machines and a flexible work capacity, we ensure that you can start welding sooner than when you would make the preparation yourself.

The box sections are bundled or crated per sub-assembly as a ready-to-weld kit and transported to your site.