About us

We automate craftmanship

to give the world of steel

the freedom create.

Our machines, your solution

We are committed to giving you the competitive advantage in your market. Helping you turn your fabrication process in a streamlined and automated manufacturing environment. Trusted by the world’s leading companies in construction, shipbuilding, offshore and pipe processing industries.

HGG is all about delivering freedom. We openly share our knowledge and expertise, actively engaging in strategic partnerships to enhance the freedom our customers experience. We are on a mission to automate craftmanship and give the world of steel the freedom to create.

3

International locations

170+

Employees worldwide

1100+

Machines installed

60+

Installation countries

Synergy

A unique synergy between

machine manufacturing and cutting services

Our strength lies in the unique synergy between our two business divisions, HGG Profiling Equipment and HGG Cutting Services. We build the world’s best 3D profiling machines in-house and use them daily for their intended purposes.

HGG Profiling Equipment

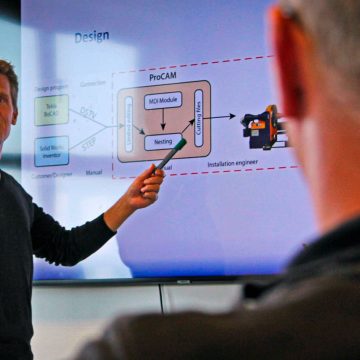

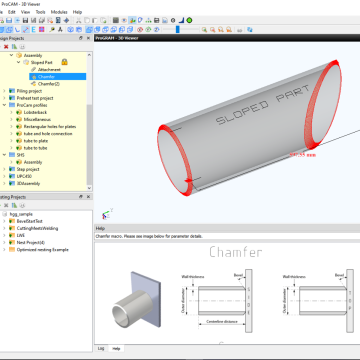

Within our own facilities, we take care of every aspect involved in the design and production of our 3D profiling machines – from the initial concept to the finished product. This includes inhouse development of our machine operating software, the brains of our machines, and HGG’s ProCAM software, which allows you to easily turn your CAD-designs into cutting files.

At HGG, we ensure that everything is created and controlled internally, providing you with a single point of contact for assistance whenever needed.

HGG Profiling Contractors

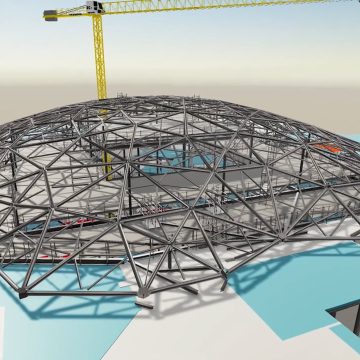

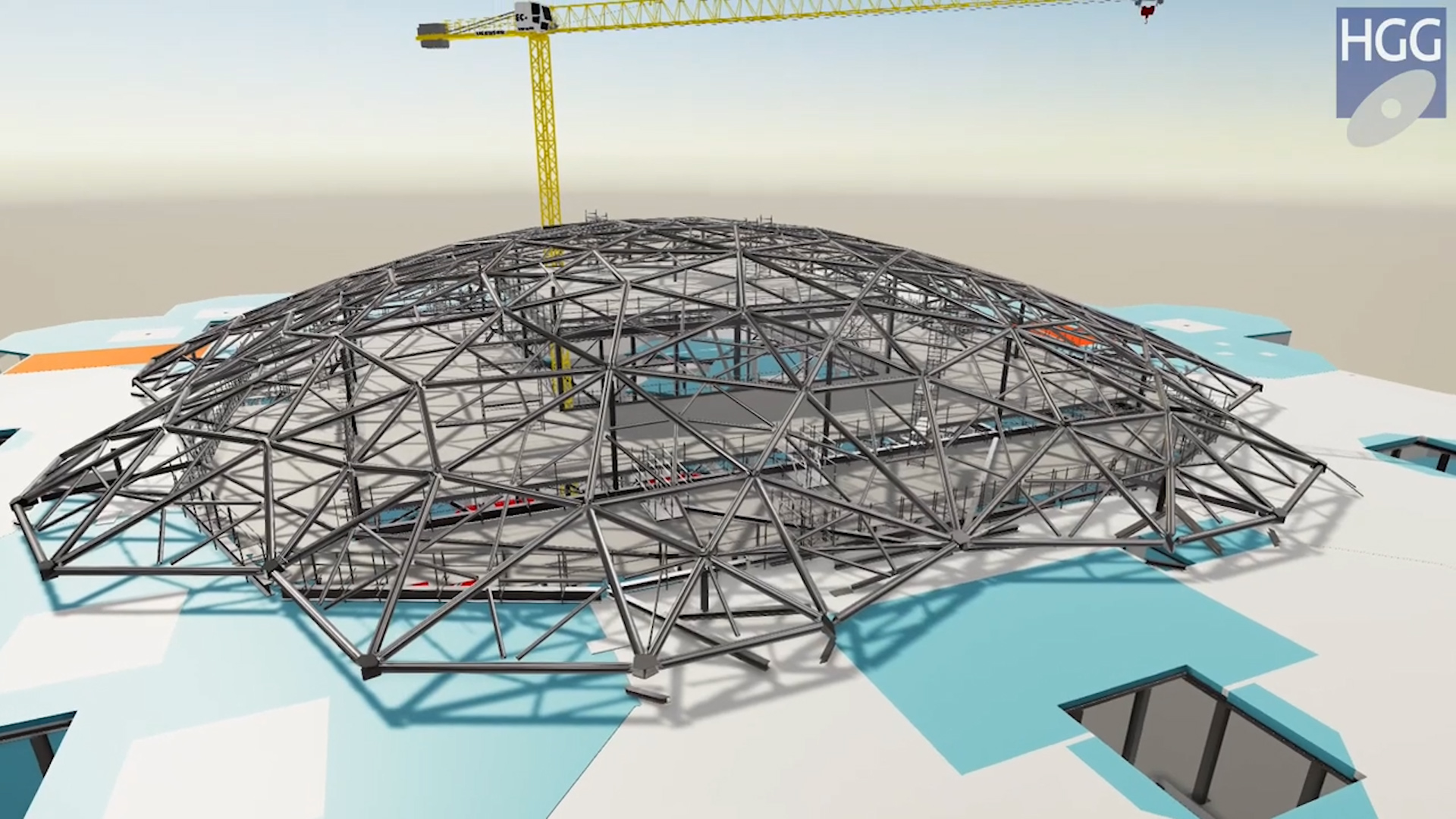

Situated at our Headquarters in Wieringerwerf, our cutting service division offers 3D profiling solutions using our in-house-built machines. Handling approximately 500 tons of materials each week, we cover a diverse range of profiles and dimensions.

We guide our customers through the entire process, from the design and detailing phase to offering logistics options for delivery, either to the customer or directly to the job site. With 40 years of experience, we use our expertise to ensure that every part is produced in the best and most efficient manner.

Strong foundation

Pushing the boundaries of what is possible

The challenges that inspired our founders back in 1985 to establish the HGG company continue to drive us to this day. We are committed to increasing productivity, reducing reliance on hard-to-find skilled craftsmanship, and meeting the demands of increasingly complex safety and quality requirements. This drive provides you with the freedom to continually push the boundaries and limitations of what is possible in the world of steel.

We ensure you can execute complicated profiling in steel pipes, beams, box sections, and other profiles, regardless of size and specifications. The machines that we develop reduce both fitting and welding time and eliminate the need for grinding away imperfections by delivering precise and clean cuts. We know this for a fact because we use them every day at our cutting shop, handling roughly 500 tons of material a week. This is why you’ll find our machines at the world’s leading construction, shipbuilding, offshore, and pipe processing companies in over 60 countries worldwide.

HGG | 3D Profiling Specialists

We automate craftmanship to give the world of steel the freedom to create!

40 + years experience

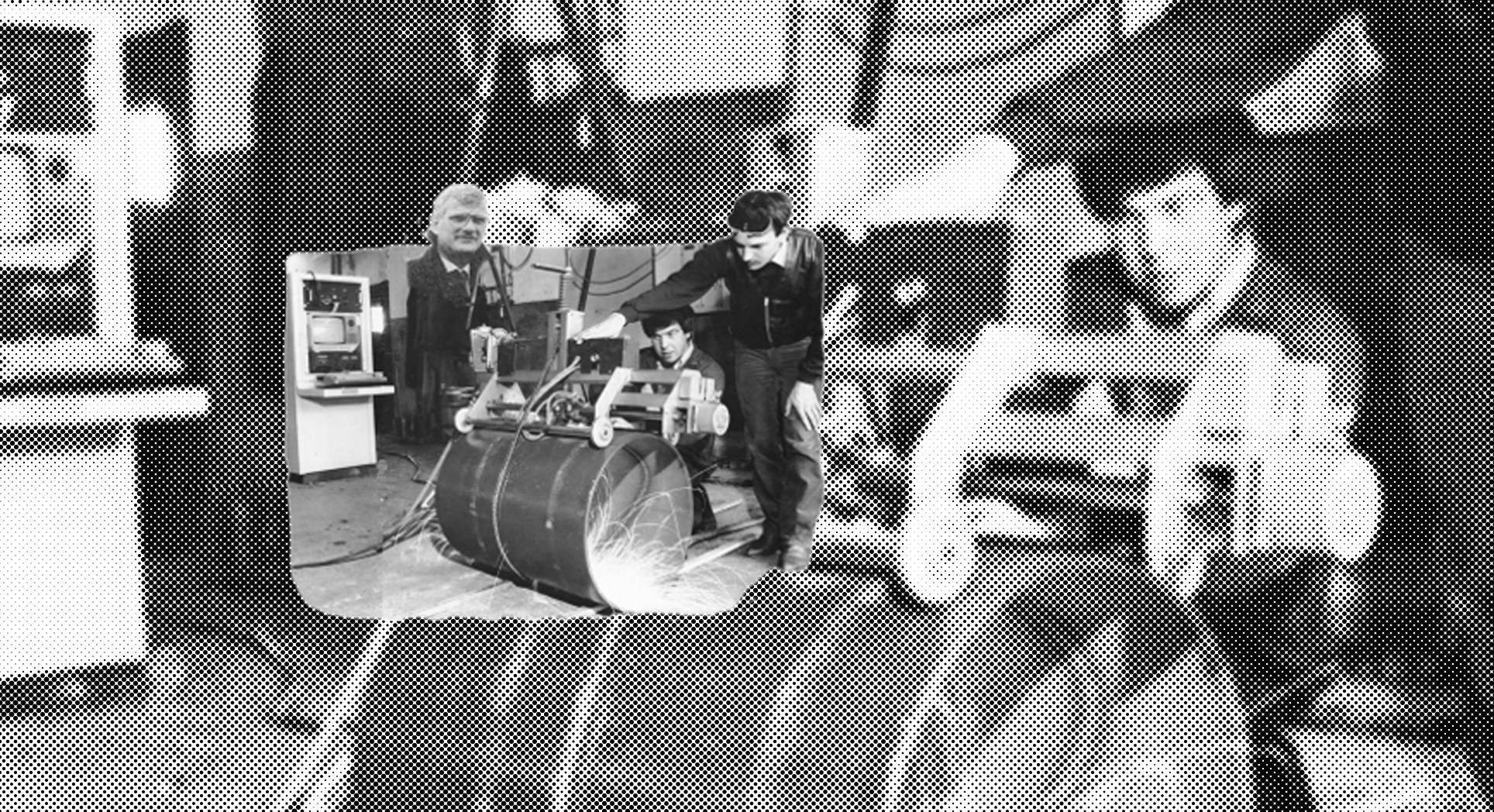

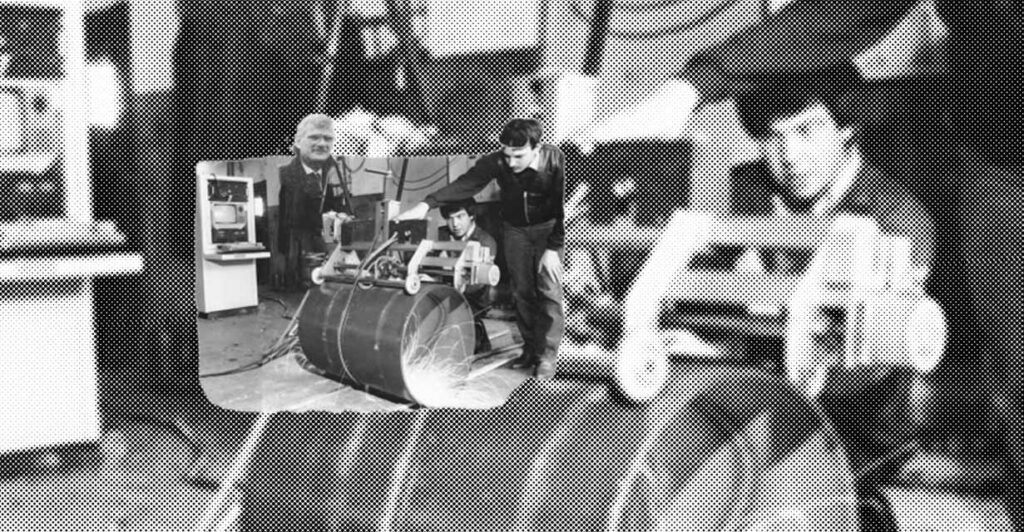

What inspired our founders back in 1984

Our story began in 1984 at a steel construction company in a small town located roughly 50 kilometers north of Amsterdam. Faced with the challenges of manually cutting steel, our founders – Hans Helmhout (H), Piet Goverse (G), and Pieter Glijnis (G) – set on a mission to develop the first pipe profiling machine.

The three engineers quickly realized that to achieve full fabrication freedom, they needed not only to increase productivity but also had to pay special attention to incorporating smart welding preparation features into their design. Shortly after successfully accomplishing their mission in 1985, the HGG Group was established by one of the three engineers, initiating our journey to continually advance the 3D profiling solutions we offer to the world.

Our Philosophy

Creating an atmosphere of mutual trust & appreciation

Within HGG there is an underlying atmosphere of mutual trust and appreciation. This extends to our customers, partners and suppliers. We highly value the opinion of our global network of colleagues and regional representatives who help us in accurately grasping cultural diversity and local market needs. This open-minded attitude enables HGG to successfully continue striving for excellence in the solutions we provide customers.

Enthusiastic to find new opportunities

Although market-driven, our work approach has always been highly innovative. We put constant effort in anticipating the future needs of customers by embracing new technologies and developing advanced solutions. Adopting innovation is the only way to sustain our team’s prominent enthusiasm for solving new challenges.

Together we achieve more

We firmly believe in teamwork and sharing knowledge. It’s this eager exchange of experience and knowledge that fuels our development and fosters the collective genius of the HGG team. The key to our success – we eagerly welcome partners and customers into the HGG family. As a result, the solutions we achieve are by-products of close cooperation and open communication. Using this formula, the HGG group is always greater than the sum of its parts.

Continuously develop our potential

Growth is crucial to sustaining continuity in a constantly evolving market and essential for the realization of ambitions. Our experience and knowledge grow every day and each new project brings us valuable new insights, which we in-turn translate into developing innovative solutions. The friendly and participative work environment at HGG nurtures our growth and provides countless opportunities for further development at both a personal and corporate level.

We are dedicated and devoted

Our passion and commitment drives us to excel in the development and realization of innovative solutions. This team dedication and enthusiasm stems from our belief in each other and the pride we take in our products. Our passion for constant improvement makes HGG unique.