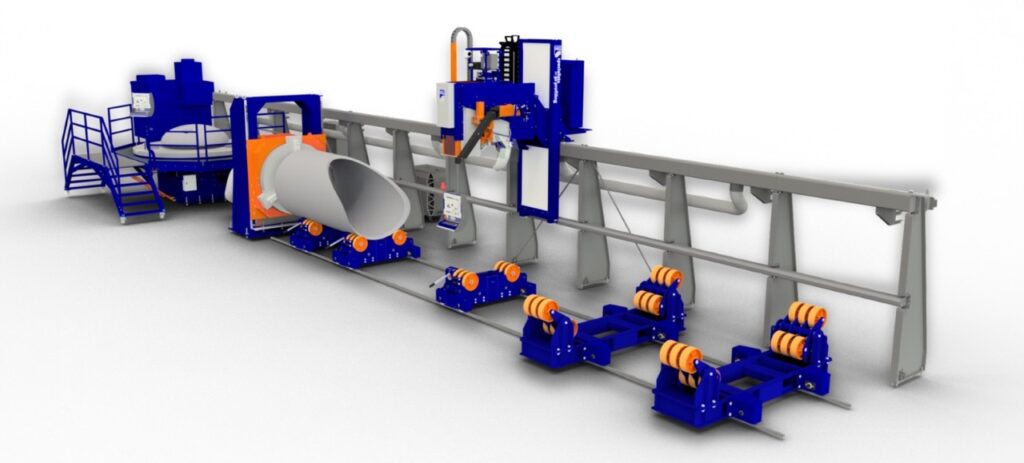

Case Study SPC 1500 - 3000 VC

HGG Case Study at Enerflex Ltd

WATCH VIDEO

About this case

introduction

Enerflex Ltd, an international company headquartered in Calgary, supplies solutions for natural gas compression, oil and gas processing, refrigeration systems and power generation equipment. Each substructure integrates a series of pressure vessels, which in-turn requires skilled and hard-to-find pressure vessel welders.

10%

Saved on labor costs

SPC 1500 - 3000 VC

25%

increase department capacity

SPC 1500 - 3000 VC

2200

Employees

Enerflex Ltd

1980

Established in

Enerflex Ltd

Precision Challenges in Vessel Fabrication

Armed with tape measures, jigs, chalk lines and acetylene torches, pressure vessel welders and fitters typically layout their work by hand, responsible for positioning extremely accurate hole locations and then cutting exact hole sizes with critical tolerances. Even small errors can result in fit-up issues, creating production delays and then quality issues and scrapped pressure vessels down the line.

Dramatic productivity gains for Enerflex

- Quality & Productivity have improved

- Pressure vessel cutting took 8-10 hours, now it takes about 1 hour

- Department capacity has increased 25 – 30%

- Reduced labor cost estimates by 10% on every fabricated pressure vessel and every order

- Plant safety has improved drastically

“From a throughput perspective, we were falling behind. We found ourselves, as a fabricator of the equipment, outsourcing into the local market. Very expensive and very long lead times. We were losing control of our quality, our projects and our schedules.”

Kurt Schaerer, General Manager at Enerflex