Case Study MPC 450 | 500 - 1200

HGG Case Study at Orion Drilling

WATCH VIDEO

About this case

introduction

Orion Drilling is a full service drilling company from Texas, USA. They’re specialized in manufacturing and fabricating oil and gas drilling rigs. The company used to subcontract as much as 25% of their fabrication. Gradually over time Orion started suffering major issues due to the low quality of the subcontracted fabrication work.

20%

Minimum improved production

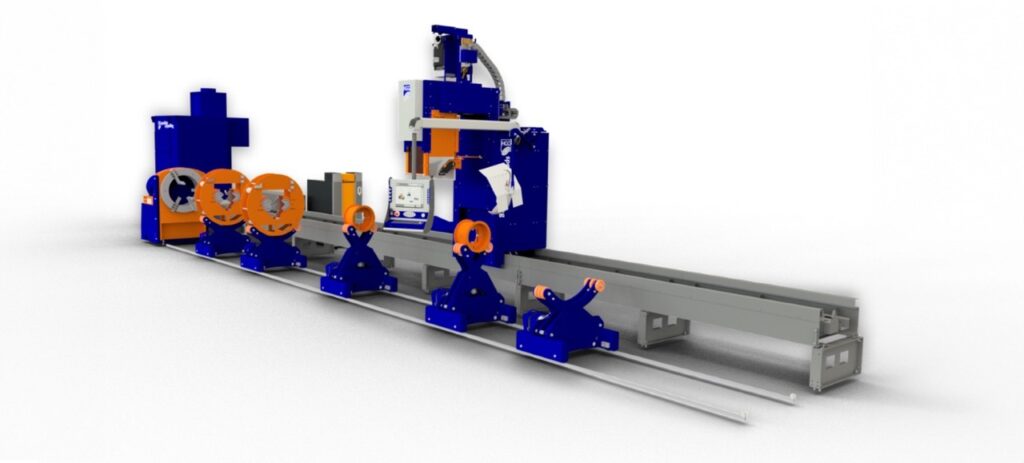

MPC 450 | 500 - 1200

2003

Established in

Orion Drilling

Reduce welding time, improve accuracy and quality

Weld draw, the metal gap that welders encounter during fit-up, must be at an absolute minimum to facilitate welding and reduce welding time, to improve overall accuracy and quality, and to maximize Orion productivity. Maintaining a tight tolerance was becoming a constant issue starting to jeopardize greatly the quality of each finished oil rig.

No need to outsource

Orion could no longer compromise on the accuracy and quality of the oil rig structures. The Texas-based company purchased the MPC 450 | 1200, HGG’s multi-profile cutting machine for pipes, square tube and flat bars. The MPC software helped Orion optimize their fitting and minimize welding volume. Unique algorithms are used to create smooth cross-overs between surfaces. E.g. the cross over from the four surfaces of a box section are extrapolated in order to create a smooth weld transition on the four no. radii.

Thanks to the smooth weld details and perfect fit length provided by HGG’s MPC 450 | 1200 pipe and tube cutting machine, Orion Drilling no longer needs to outsource to fabricators and their welders now do only what they are really good at – fitting and welding.

"Maintaining a tight tolerance was a constant issue and problem. For us, the final straw was a situation where we had to disassemble an entire oil rig and scrap it because the quality was simply not there."

Mr. Ram Cortez, Production Manager