Our RPC 1200 Mk3 Beam Cutting Machine changed the market from the day it was introduced. Originally developed for the offshore market, it found its way quickly into the steel construction industry. Offering, uncompromised accuracy, the capacity to cope with all profiles, and high-speed production, all included in a small footprint machine. In this product walkthrough video, Matthew takes you on a tour through the inner workings of the RPC, showcasing the unique features it has to offer, quickly explaining how all the components work.

Watch the video

Our unique robot application

The RPC is equipped with the Stäubli TX2 90 Robot. This robot features six axes, offering both longitudinal and height axes. This setup enables us to reach around even the largest materials without any issues. However, the true magic of the robot comes from the software developed in-house at HGG. Thanks to HGG’s unique application of the robot, high positioning accuracy is achieved. While most machine fabricators quote the repeatability accuracy of their robot applications, the HGG system distinguishes itself by rapidly and accurately measuring to immediately correct the theoretical cutting path. This increases the machine’s productivity by up to one and a half times without compromising accuracy.

Laser Scanning Technology for Extreme Accuracy

The longitudinal position is measured by rollers placed against the flanges and a laser measurement system. To measure and compensate for the distortions and deviations of profiles, the RPC is equipped with multiple measurement positions. The scanner scans the material before cutting, after which one or multiple cutting routines can be performed. The scans can be reviewed, providing the operator with a reference for what has been measured. The alignment of the material is verified to check if the profile is off-center in the cutting cell, which usually indicates that the profile is bow-shaped, bent, or twisted.

A Safe, Strong, and Easy-to-Transport Cutting Cell

The multifunctional cutting cell is the heart of the robotic profiling machine. It provides the sturdy base required for plasma cutting while simultaneously protecting the operator from noise, sparks, and plasma fumes. We’ve designed the cell so it doesn’t need to be assembled but can be shipped directly in a container to minimize delivery times.

The RPC Can Truly Cut It All

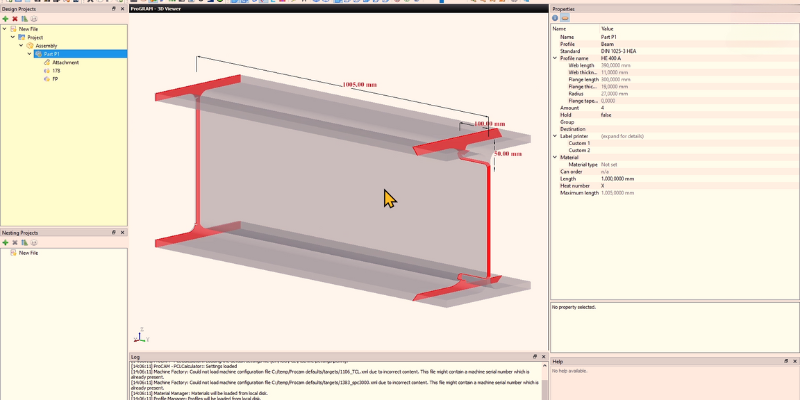

Beams, boxes, pipes, T-bars, channels, bulbs, flat-bars, angles, and uneven angles — the RPC 1200 Mk3 truly cuts all profiles. It can perform weld preparations, simple straight cuts, outfit markings, and hole penetrations. The RPC doesn’t care whether it’s a simple hole or the most complex bevel. Simply import your NC or STEP data into HGG’s ProCAM software and take advantage of the RPC’s versatility.

➡️Want to know more on the RPC 1200? Find out all about this machine on the RPC 1200 Mk3 product page.