When cutting thick walled material, like pressure vessels, it is difficult to define the perfect time and temperature to pre-heat so that even the deepest part of the material is heated to the correct temperature. It requires a lot of practice and experience.

When thick walled material is pre-heated for slightly too long, the input of oxygen will cause a lot of spatter and create a large crater. This is due to the thick wall and excessive amount of liquid slag. On the other hand when insufficient pre-heating is applied, the full wall thickness will not reach the ignition temperature to maintain the exothermic process. The process will stop half way and the operator will have to try again at another starting point and the damage to the fitting contour will require a lot more grinding and welding.

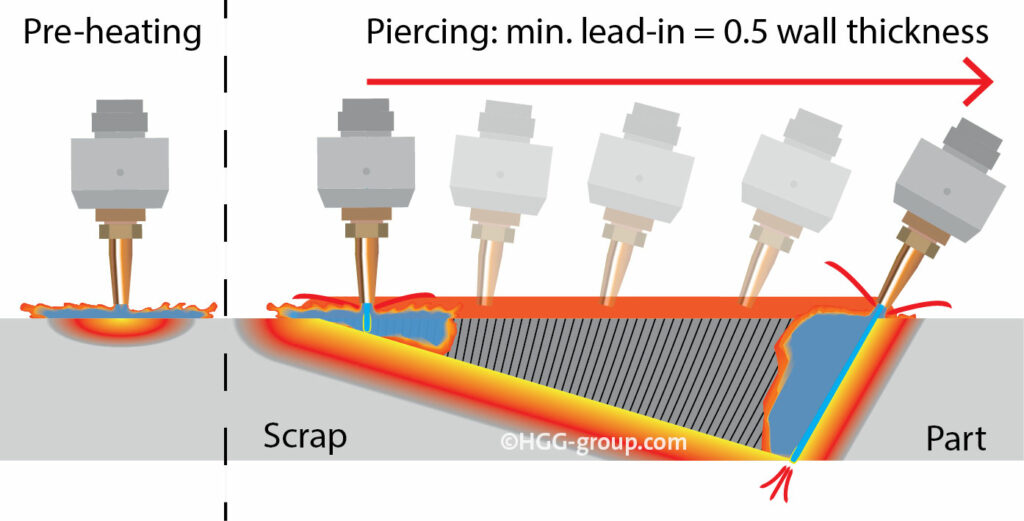

Proportional piercing

To automate this process a method called proportional piercing can be applied by which the oxygen flow is regulated in order to control the exothermic process during piercing. After a very short period of pre-heating to make the material surface reach the ignition temperature, the piercing process is started at a low oxygen pressure. As the torch starts moving towards the initialisation point of the programmed fitting contour, it gradually changes angle while at the same time the oxygen pressure is gradually increased to maximum pressure to keep the exothermic process running and to pierce deeper. The tilting creates room for the liquid slag also results in a minimum of spatter (protection of cutting tip).