Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

CUSTOMER CASE:

Solution Steel | RPC 1200 Mk3

CUSTOMER CASE:

Coenen Mechanical LLC | PC 900 RB

CUSTOMER CASE:

Aker Solutions | Offshore Solutions

Think global, act local.

With over 40 years of 3D Profiling expertise.

Specialists in 3D Profiling since 1984

In 1984, three engineers joined forces to develop the first pipe-profiling machine, addressing the need for higher productivity and incorporating smart weld preparation features.CEO

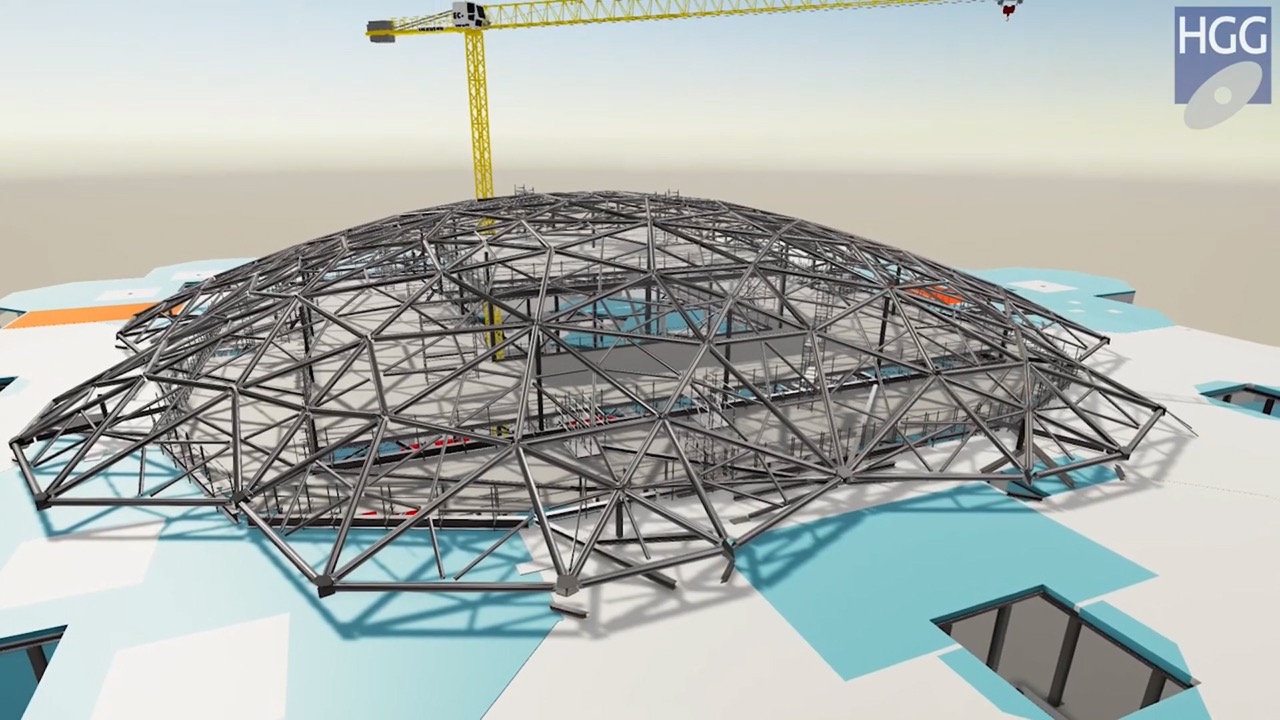

Giving the world of steel the freedom to create

Our advanced smart cutting solutions offer companies across the globe the freedom to design and create some of the most iconic and innovative structures ever built. We empower our clients to push the boundaries of what's possible.

Building machines, and using them daily

We don't just build the world’s best 3D profiling machines in-house; we use them daily for their intended purposes. Handling approximately 500 tons of materials each week and covering a wide range of profiles.CEO

With over 1100+ machines installed worldwide

Over the years our engineers have travelled the world, installing HGG machines across the globe. Bringing our cutting-edge technology to every corner and giving companies worldwide the freedom to create.

And a team of 170+ professionals

Our team always strive to break new ground and lead the way in 3D profiling, making a name for ourselves as innovators in the market. This mentality is vital to who we are and what we do.CEO

Our machines

Which Profile Shape Do You Need To Cut?

Find the machine you’re looking for

Which Profile Shape Do You Need To Cut?

Industries

Industries that benefit from our solutions.

Industries

Industries that benefit from our solutions.

Case studies in your industry

Trusted by the world's leading companies.

Industries

Industries that benefit from our solutions.

“The HGG is the

heartbeat of the shop.

It drives what gets done

on a daily basis.”

heartbeat of the shop.

It drives what gets done

on a daily basis.”

Mark Janning, Fabshop Manager, MMC Contractors

Steel Construction

Client

Griffin Welding

Industry

Steel Construction

MachineRoboRail

Location

Connecticut, the United States

Offshore industry

Client

LJUNGSTRÖM LLC

Industry

Offshore industry

MachineRPC 1200 Mk3

Location

New York, the United States

Process

Client

Bassett Mechanical

Industry

Process

MachineProCutter 900 RB

Location

Wisconsin, the United States

Offshore industry

Client

Mostostal Pomorze SA

Industry

Offshore industry, Steel Construction

MachineMPC 450 | 500 - 1200

Location

Gdansk, Poland

Steel Construction

Client

Coenen Mechanical LLC

Industry

Steel Construction

MachineProCutter 900 RB

Location

Wisconsin, the United States

Looking for sales support?

Reach out directly to our sales manager for expert advice on solutions. Call or email me directly – I am here to help!

Stay up to date

Subscribe to our newsletter to get the latest on our solutions and developments.