Product Tour ProCutter 600 - 900

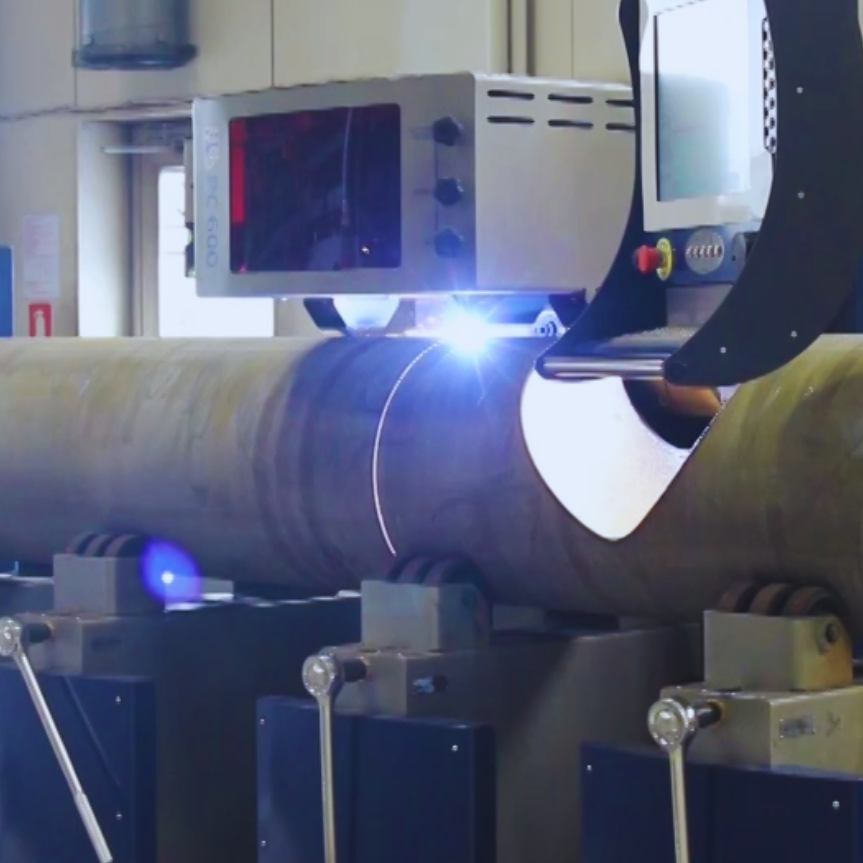

Plasma Pipe Cutting within Reach

WATCH VIDEO

CNC Pipe Cutting Within Reach

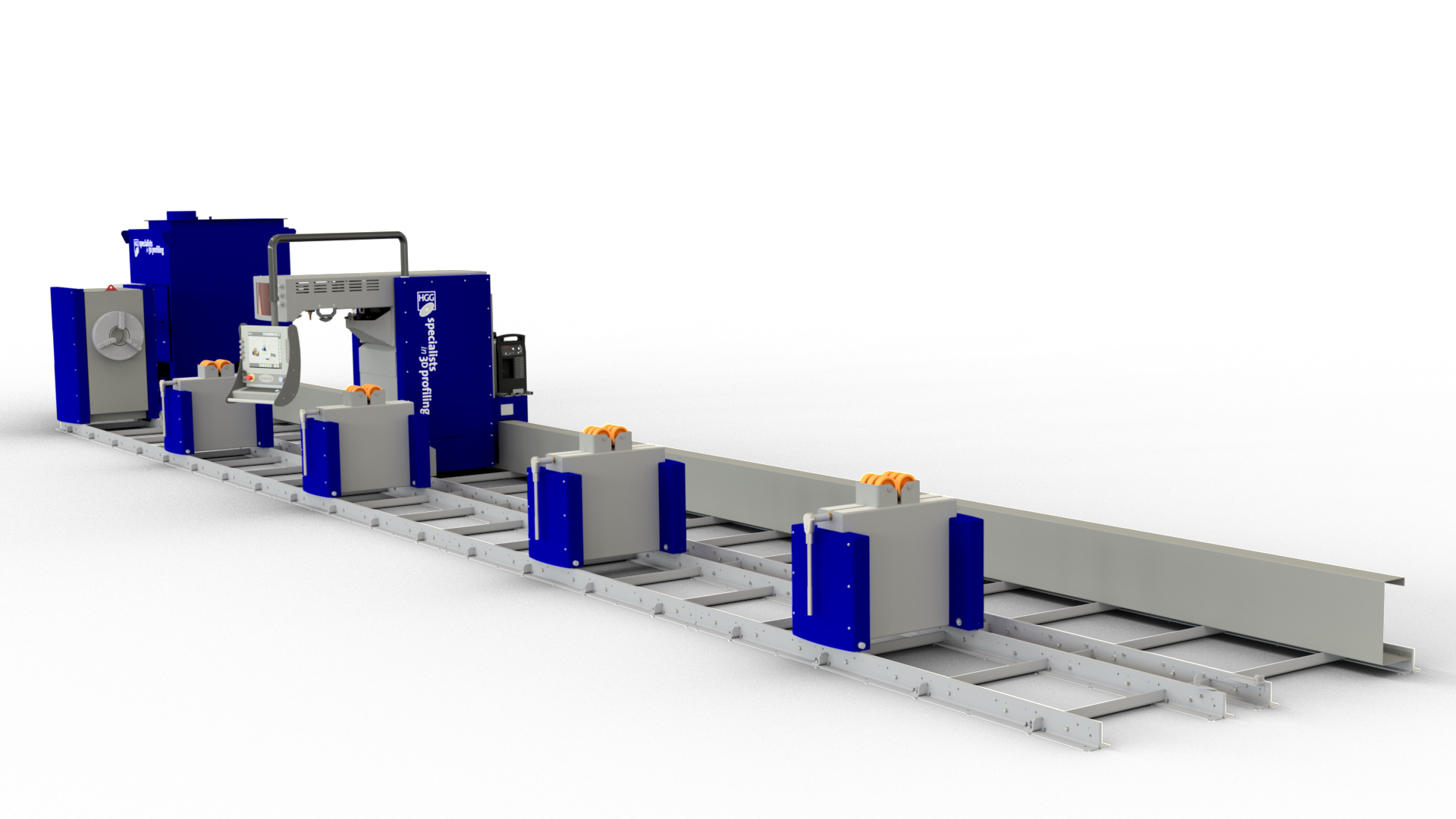

The ProCutter 600 – 900 is a CNC pipe cutting machine that clamps and rotates the pipe in a chuck during cutting. It offers excellent value for money, delivering 3D profiling with high precision and ease of use. Designed for flexibility, it can be configured to meet your specific needs, with each option offering unique benefits that enhance both versatility and productivity.

Specifications

Profile & Dimensions

- Profile

- Machine type

- Minimum

- Maximum

| ProCutter 600 | 48 mm | 610 mm | |

| ProCutter 900 | 48 mm | 910 mm |

| ProCutter 600 | 2 “ | 24 “ | |

| ProCutter 900 | 2 “ | 36 “ |

Additional Specifications

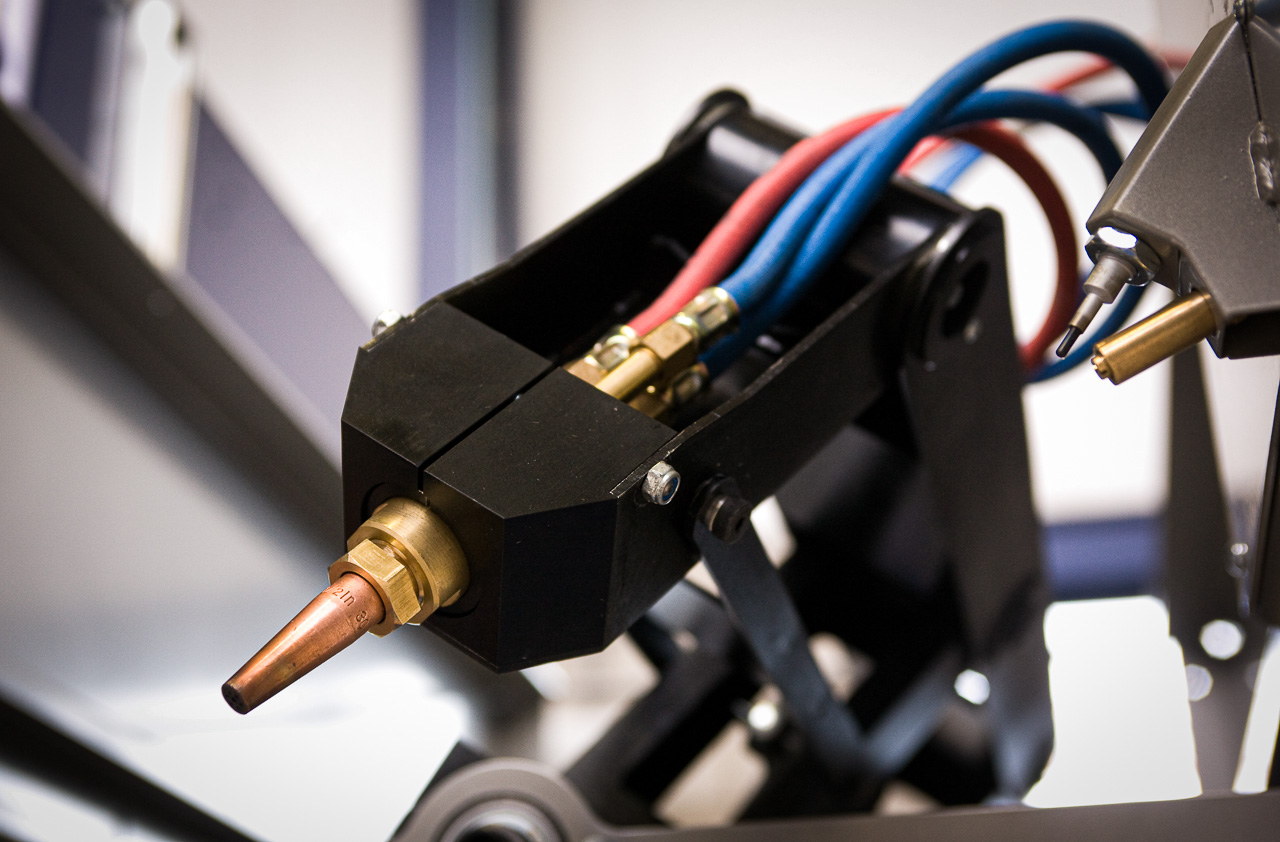

- Oxyfuel cutting

- Plasma cutting

- Plasma marking with cutting torch

- Plasma powersource: Hypertherm or Kjellberg

- Maximum Cutting Angle: 45 degrees

- CAD Connection

Discover the possibilities of the ProCutter 600 - 900

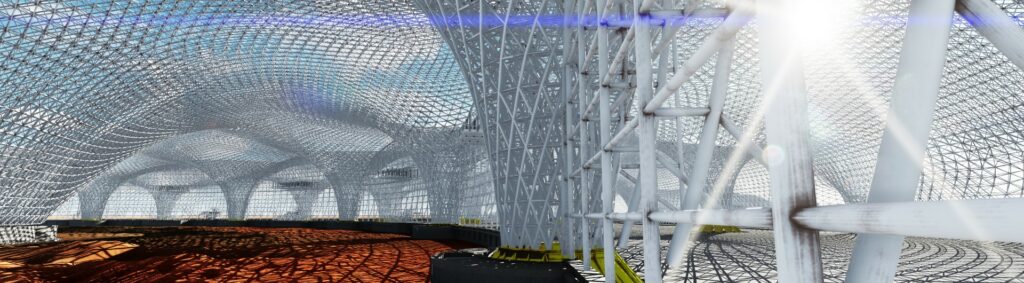

Process Piping

The ProCutter is the ideal machine for piping, capable of cutting chamfers, saddles, and holes, all ready for fitting and welding.

Line and Text Marking

Marking reference lines to significantly reduce fit-up time. Text marking can also be used for tracking and tracing cut parts.

Hole Cutting

The ProCutter can cut holes for both structural and process piping purposes.

Special Weld Preparations

The ProCutter supports special weld preparations for structural purposes to simplify the welding without compromising on strength.

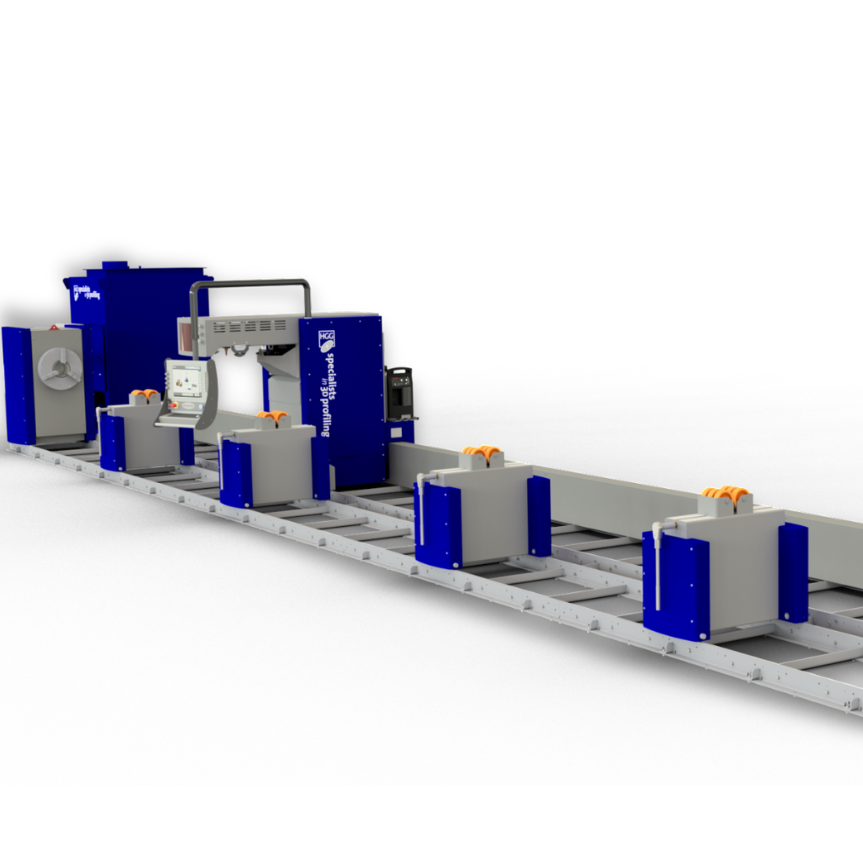

Opt for Pipe Trolleys, Rollerball Gutter or a combination

The logistics of the ProCutter 600 – 900 are adjustable to match your ideal fabrication setup. You can choose to use Pipe Trolleys, a Rollerball Gutter, or a combination of both. Additionally, you can incorporate a storage area for pipes awaiting further production.

Each setup offers unique benefits. For instance, the Pipe Trolleys, equipped with Polyurethane-coated wheels, eliminate the impact of bow-shaped pipes, ensuring precision and consistency in operations. The Rollerball Gutter setup provides rapid handling capabilities, further optimizing productivity and workflow efficiency.

No civil works required with it's build-in frame

The entire frame will be mounted on top of a concrete floor by chemical anchors to create a solid foundation.

This foundation remains aligned for years of production and is important to ensure the machine accuracy. The frame supports the main drive with chuck, cutting trolley with touch screen and pipe support. The rails on the frame allow longitudinal movement of the cutting trolley and pipe support.

Robust self-centering three jaw chuck

Because every pipe has some degree of distortion in the length (bow shaped) and roundness (ovality) the centerline is the only fixed reference point.

The most important function of the main drive is to ensure the accuracy of the pipe cutting process. The self-centering three jaw chuck achieves this accuracy by clamping the pipe securely, avoiding slip during rotation and creep (longitudinal movement). The pipe is manually clamped and can be unfastened using a wrench.

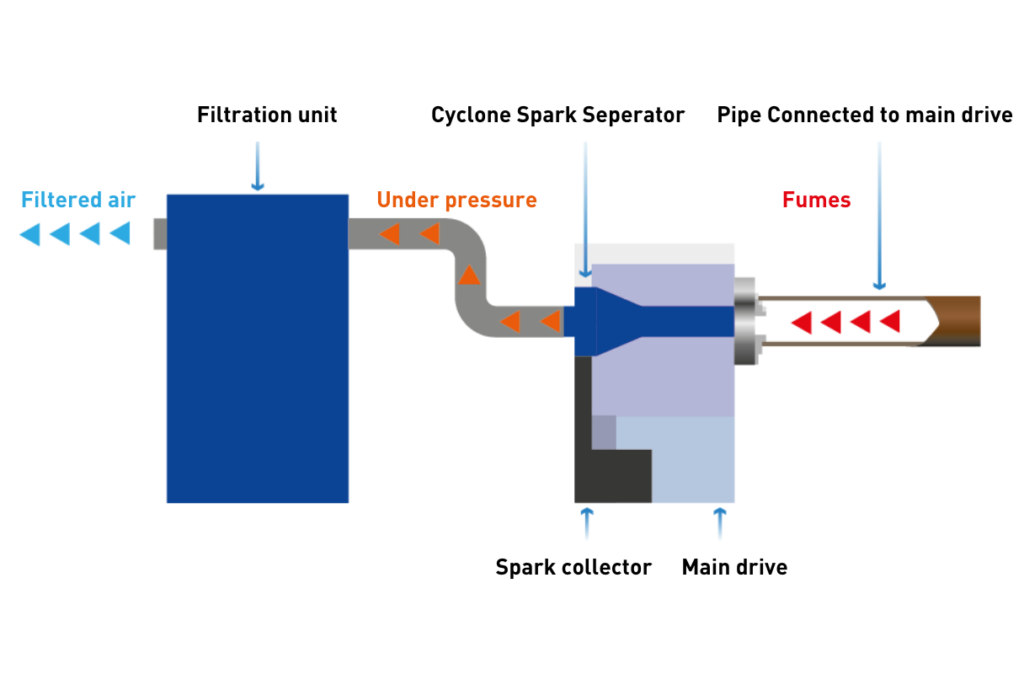

Fume Extraction & Filtration: Protect Operators and Extend Machine Life

Fumes, especially plasma fumes, can cause serious health problems, and the fine particles can decrease the lifespan of the machine and its components. The ProCutter 600 – 900 is designed to extract fumes by suction through the pipe and main drive. The extracted fumes contain sparks and are separated using a passive cyclone inside the main drive.

Filtration can be done by a separate filtration unit, or where possible, the exhaust can be directly connected to the production facility’s main exhaust and filtration system.

Featured Case Study

'Our capacity and production would be severely reduced without having this machine. It’s literally the drumbeat of the operation.'

Tyler Glaze - Sealevel Construction