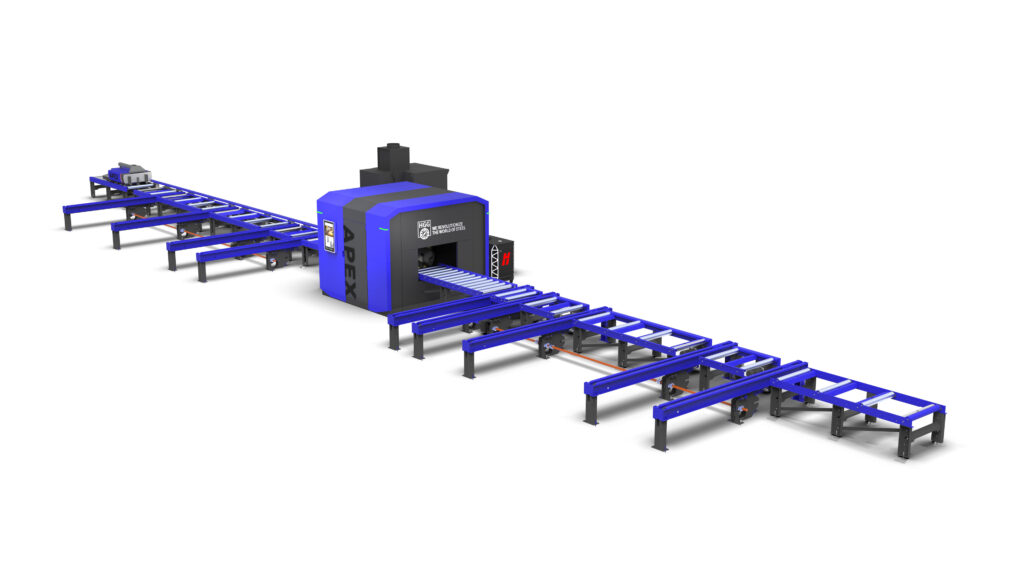

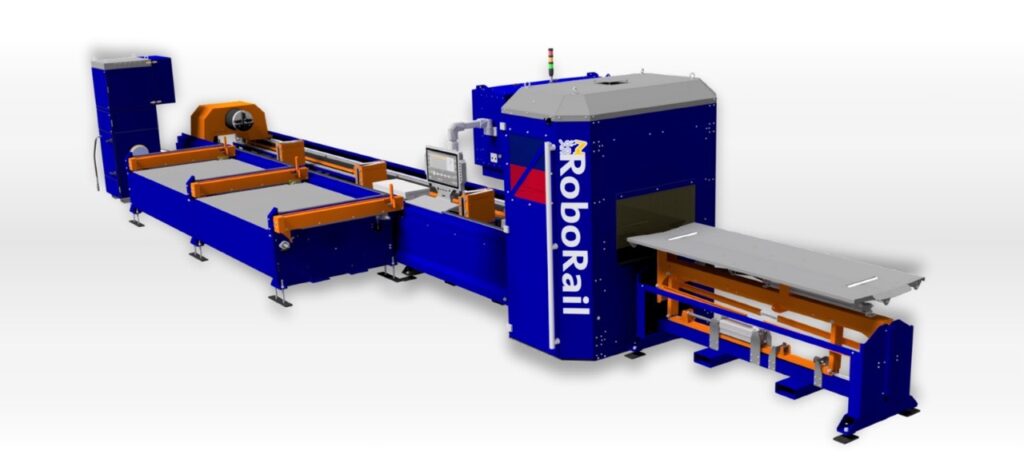

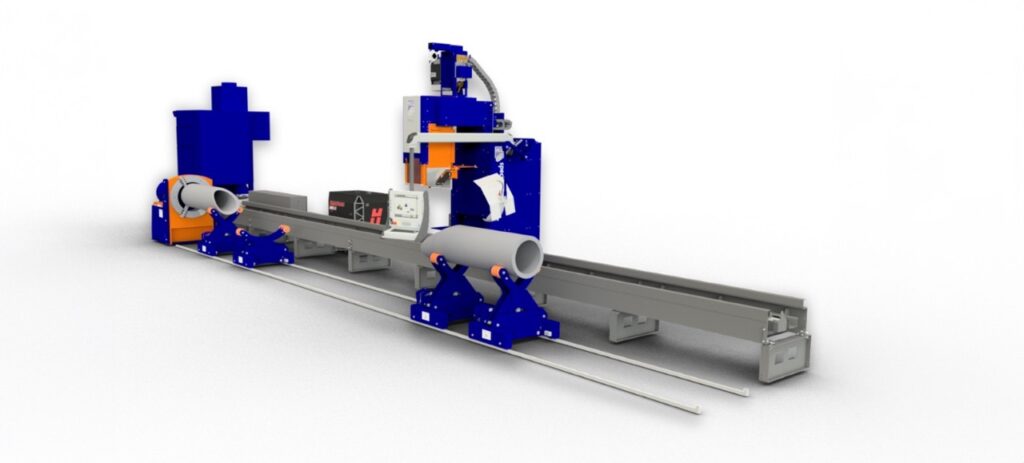

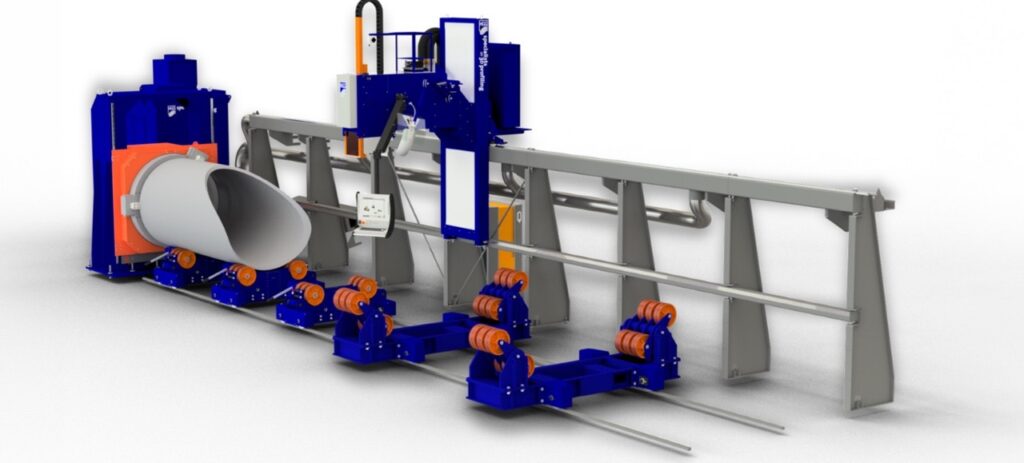

Our machines

Witness the power

of cutting-edge technology.

Looking for sales support?

Reach out directly to our sales manager for expert advice on solutions. Call or email me directly – I am here to help!

Bart Scheringa

Area Sales Manager Europe

Select your profiles (multi-select)

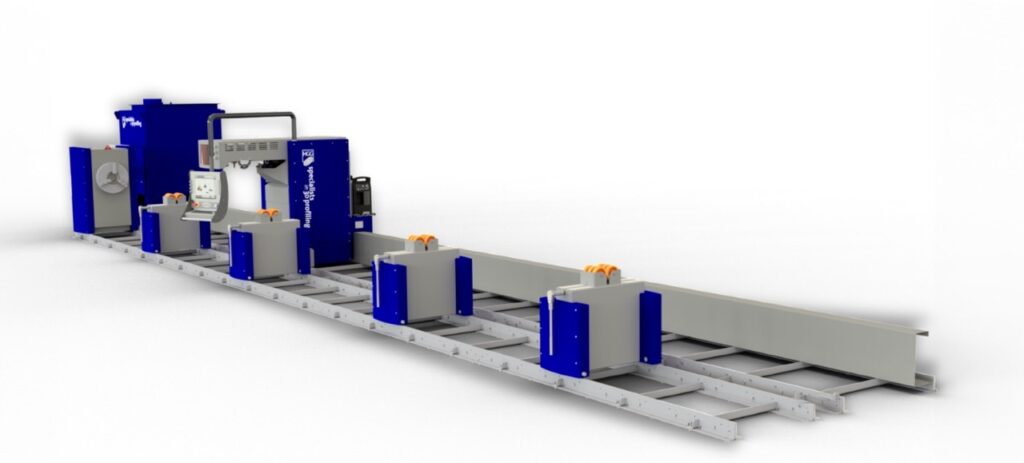

Profile shaping

Industry

Offshore, Steel construction

Process

Industry

Steel construction

Process

Industry

Steel construction

Process

Industry

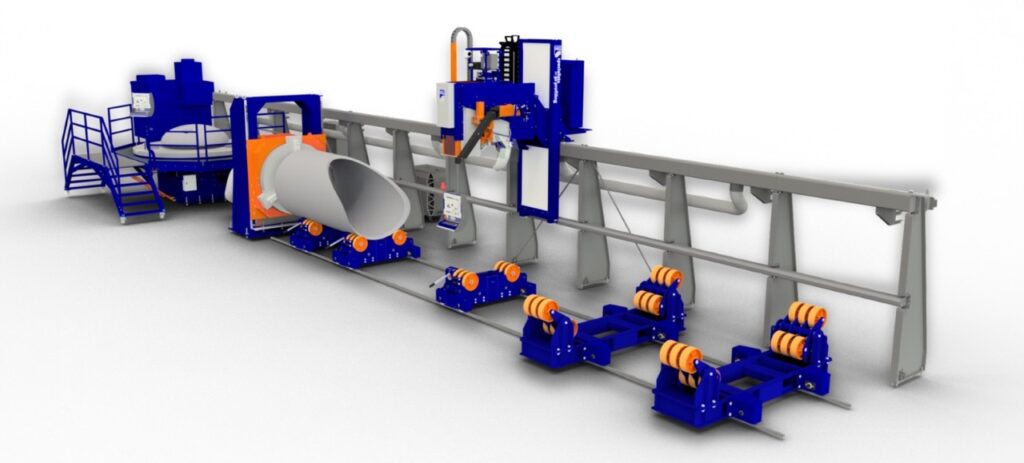

Shipbuilding, Offshore, Process, Steel construction

Process

Industry

Shipbuilding, Offshore, Process

Process

Industry

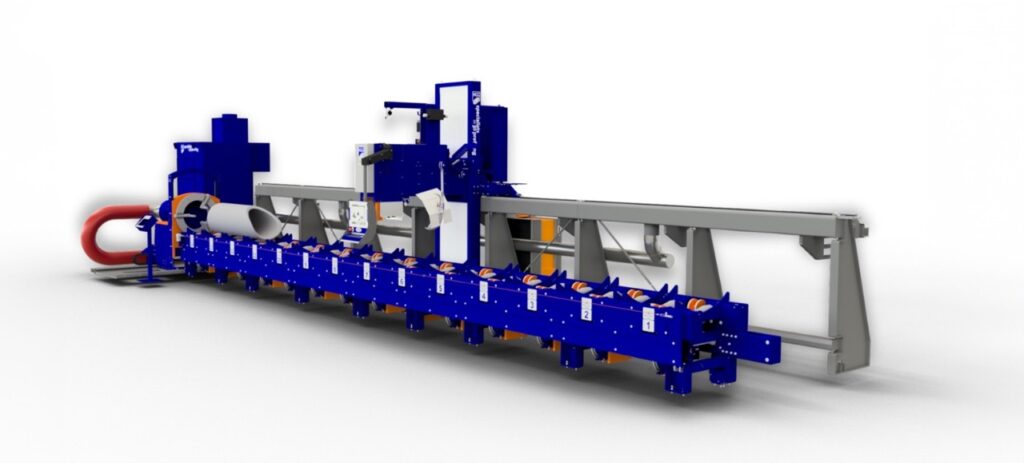

Shipbuilding, Process, Steel construction

Process

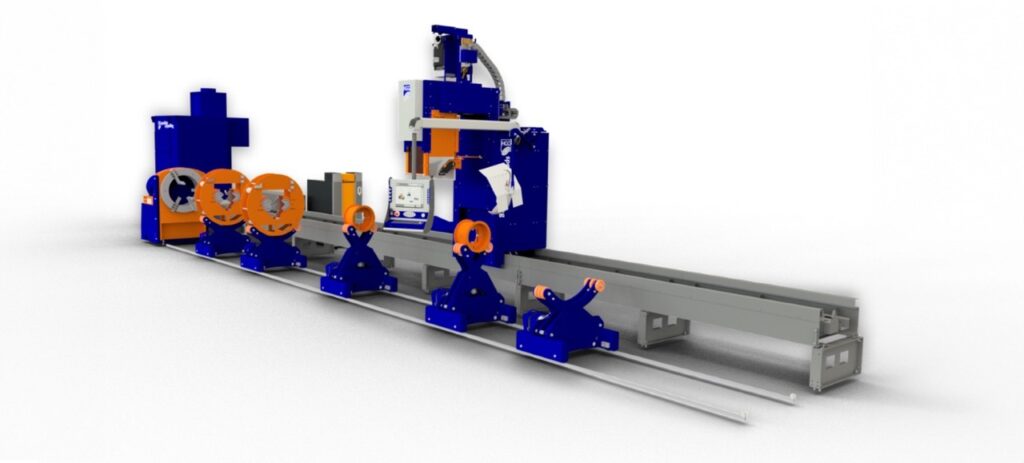

Industry

Shipbuilding, Process, Steel construction

Process

Industry

Process

Process

Industry

Shipbuilding

Process

Industry

Offshore, Process, Steel construction

Process

Industry

Shipbuilding, Offshore, Process

Process

HGG’s CNC cutting machines and cutting services, our two business entities, form a unique synergy within the steel fabrication market. Unlike others, we not only develop and build customized CNC cutting machines for 3D profiling; we also perform cutting services for third parties on our in-house built machines. With our unique combination of CNC cutting machines and cutting services, you can have pipes and tubes, beams, box sections, vessel heads or other profiles cut extremely accurately and with a bevel for faster fitting, providing smaller weld volume and shorter fabrication time.

Looking for sales support?

Reach out directly to our sales manager for expert advice on solutions. Call or email me directly – I am here to help!

Stay up to date

Subscribe to our newsletter to get the latest on our solutions and developments.