Product Tour MPC 450 | 500 - 1200

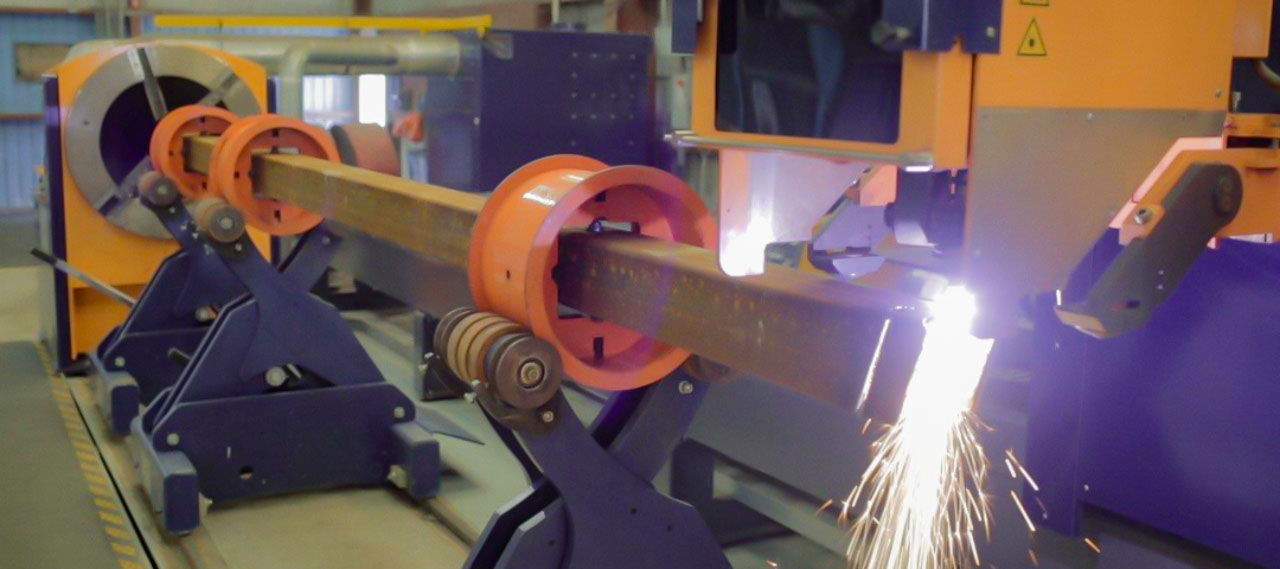

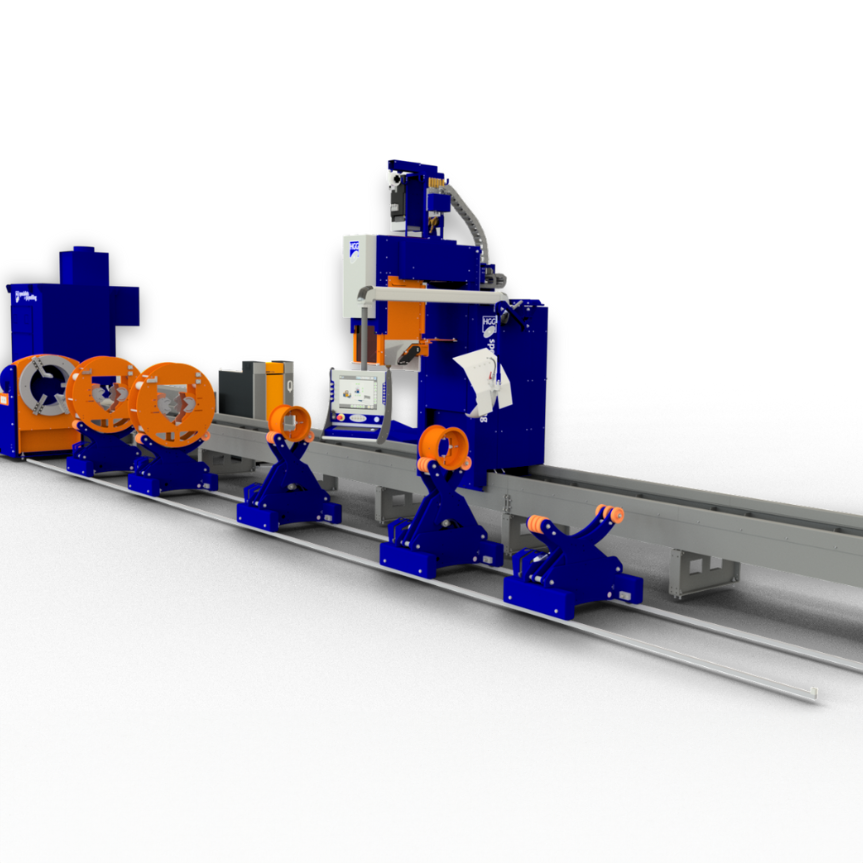

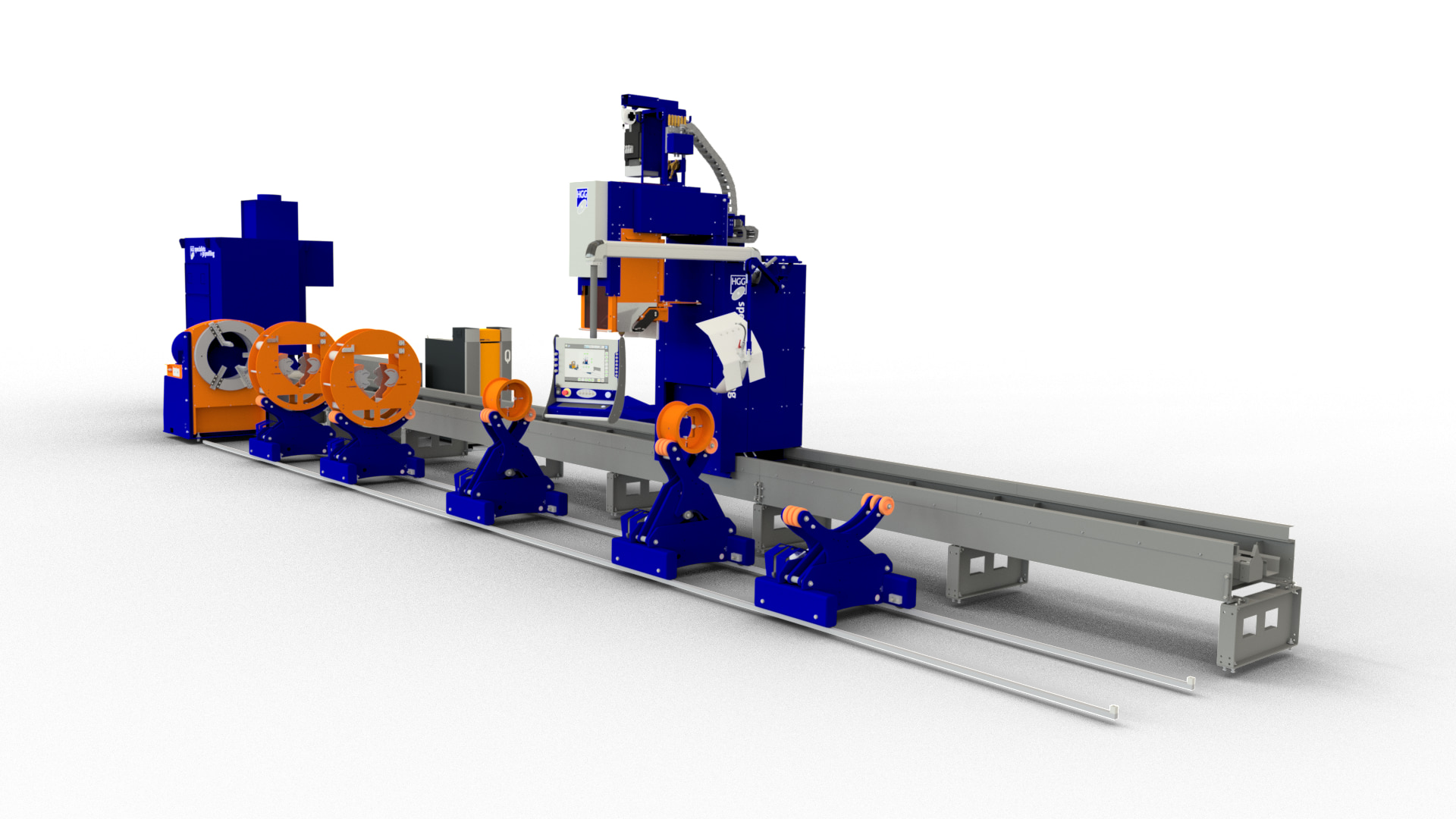

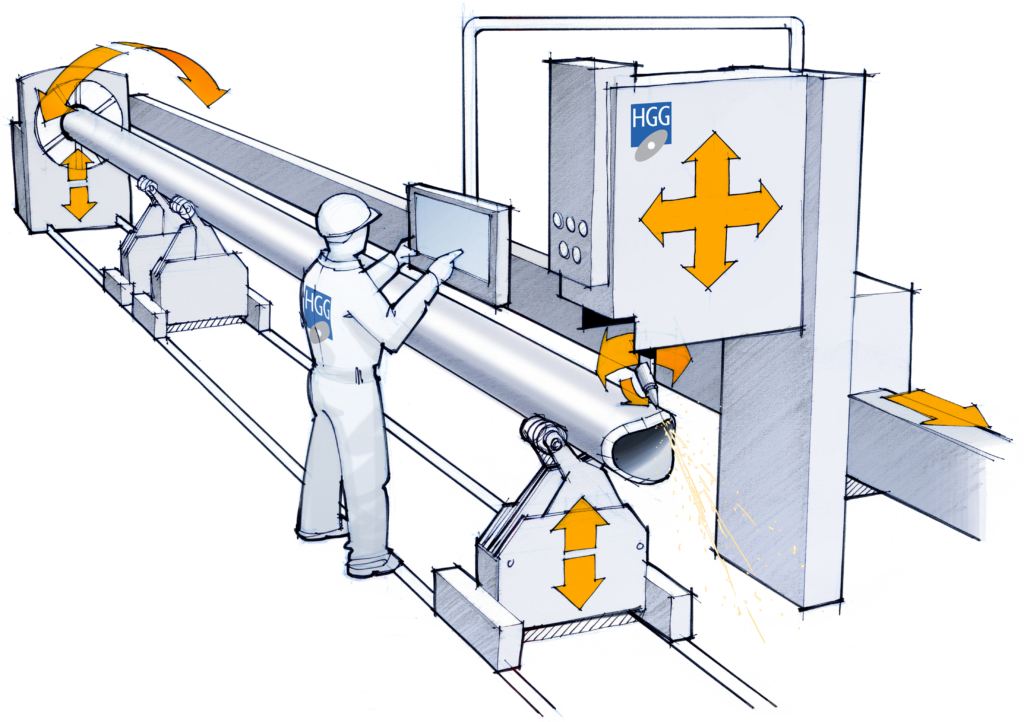

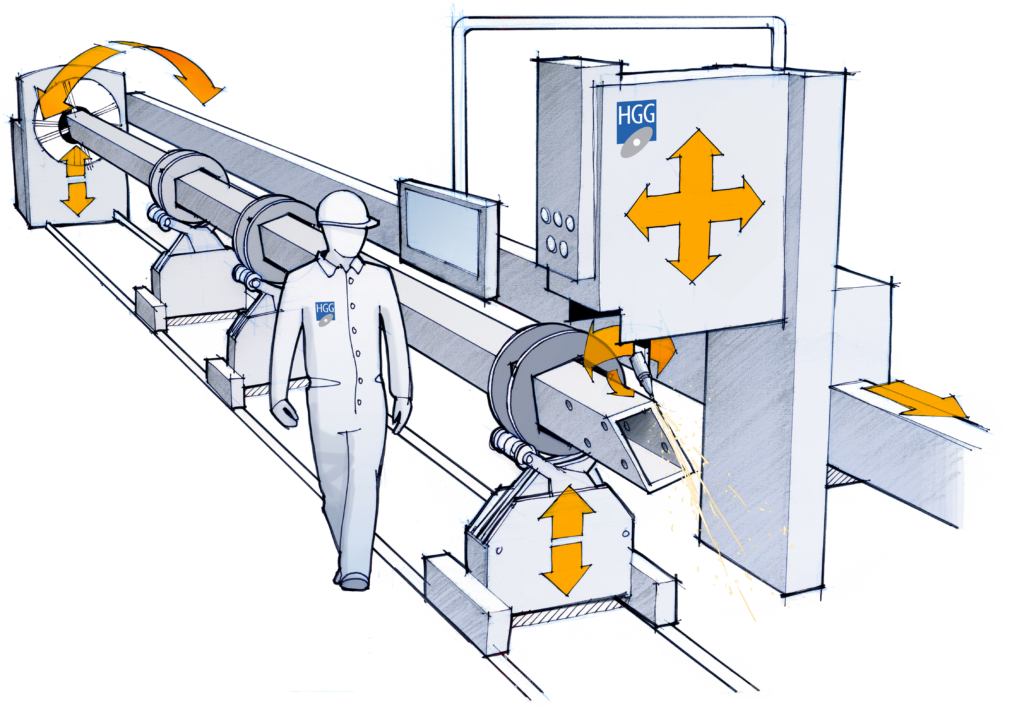

Cut your Pipe & Box profiles on 1 single machine with the MPC 450 | 500 - 1200.

WATCH VIDEO

Combine 3 Machines in One

The MPC 450 | 500 – 1200, our Multiple Profile Cutter, is the ultimate solution for versatile cutting needs, offering the ability to cut not only pipes but also a variety of other profile types. Perfect for situations where production volume doesn’t warrant a dedicated pipe profiling machine, the MPC provides flexibility and adaptability across multiple applications. With several configuration options, the MPC can handle pipes, box sections (SHS/RHS) and sheet metal strips. This makes it a multipurpose powerhouse, ideal for maximizing productivity while minimizing the need for multiple machines.

Specifications

Profile & Dimensions

- Profile

- Machine type

- Minimum

- Maximum

| MPC 450 | 500 | 48 mm | 510 mm | |

| MPC 450 | 600 | 48 mm | 610 mm | |

| MPC 450 | 800 | 48 mm | 815 mm | |

| MPC 450 | 1000 | 48 mm | 1020 mm | |

| MPC 450 | 1200 | 48 mm | 1225 mm | |

| All editions | 60 x 60 mm | 450 x 450 mm | |

| All editions | 100 x 10 mm | 400 x 40 mm |

| MPC 450 | 500 | 2 “ | 20 “ | |

| MPC 450 | 600 | 2 “ | 24 “ | |

| MPC 450 | 800 | 2 “ | 32 “ | |

| MPC 450 | 1000 | 2 “ | 40 “ | |

| MPC 450 | 1200 | 2 “ | 48 “ | |

| All editions | 2-3/8 x 2-3/8 “ | 18 x 18 “ | |

| All editions | 3-7/8 x 3/8 “ | 16 x 2 “ |

Additional Specifications

- Oxyfuel cutting

- Plasma cutting

- Plasma marking with cutting torch

- Plasma powersource: Hypertherm or Kjellberg

- Maximum Cutting Angle: 70 degrees

- CAD Connection

- Material thickness between 3 - 40 mm or 2/16 - 1-5/8 inch

Discover the possibilities of the MPC 450 | 500 - 1200

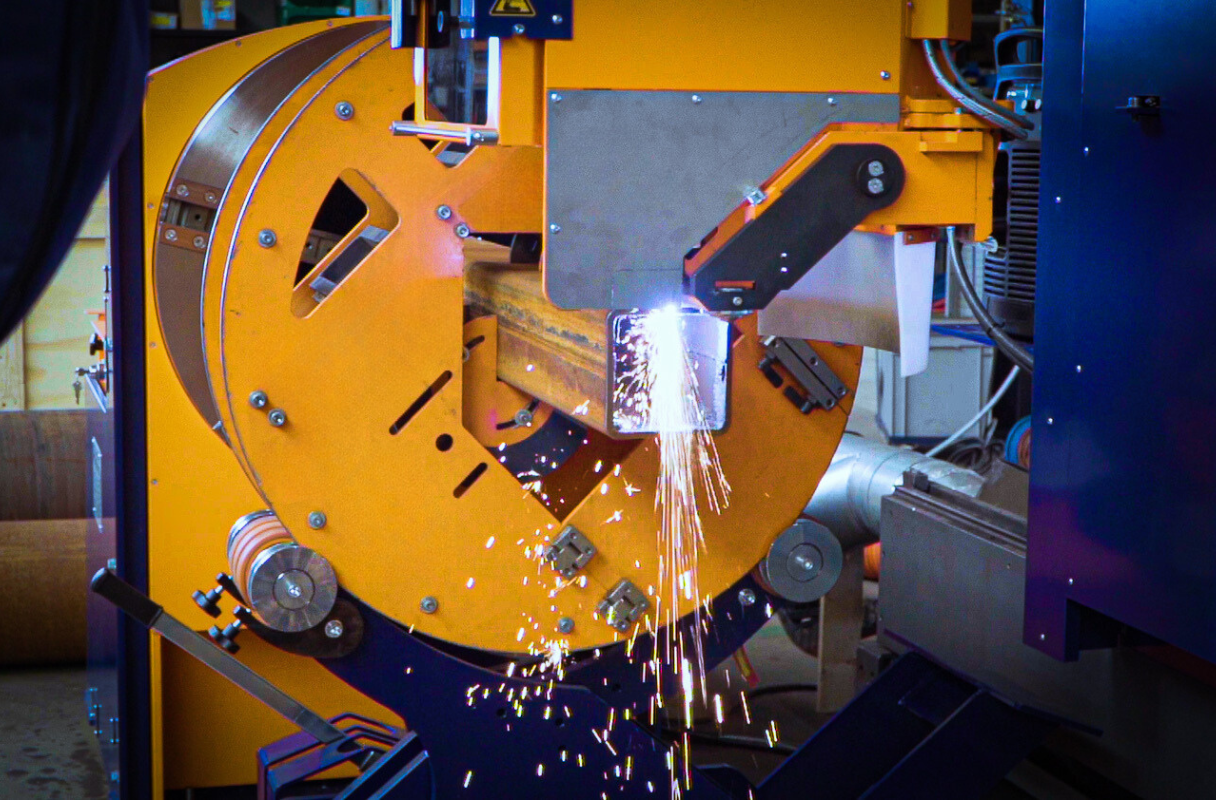

Square Tube Cutting

Cut any shape including advanced weld preparations.

Sniped Slot Holes

Example of sniped slot holes used for high strength pipe to plate connections.

Slot Hole Cutting

Slot holes combined with a snipe shape are ideal for gusset plate connections.

Consistent Precision with Every Cut

Cut with extreme accuracy

The MPC utilises software based cutting compensations of material imperfections and tolerance discrepancies to achieve the most accurate cuts. Due to the intelligence of the machine, it is possible to achieve a minimum usage of consumables and high cutting speeds without compromising on quality.

Square tube cutting with its 6th axis

This MPC 450 | 500 – 1200 not only cuts pipes but also square tubes / box profiles. It uses a 6th axis to perform uncompromised 3D cutting. The machine scans the material first by laser, to compensate for material deformations and misalignment.

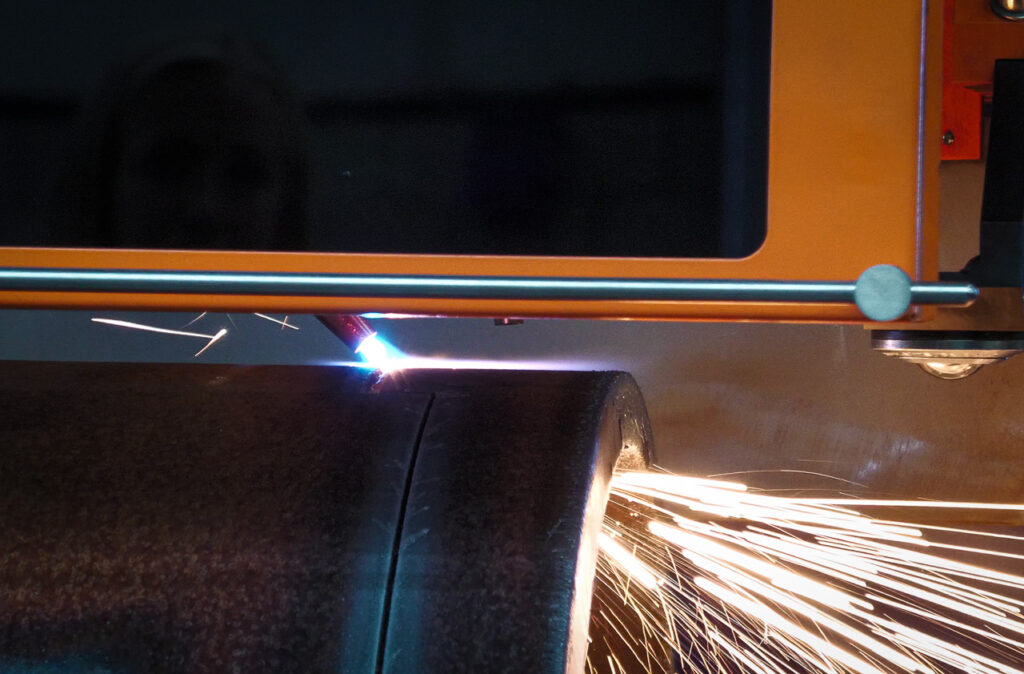

Cut with Oxyfuel

Oxyfuel cutting is a reliable, accurate and competitive cutting technique used for the cutting of mild steel. The very first HGG pipe profiling machines, made back in 1984, were equipped with oxyfuel cutting equipment.

Cutting heavy walled pipes with oxyfuel can be a challenging job. And you want to avoid making mistakes during the cutting of these expensive pipes. We developed a gas control system which creates the correct gas mixture based on material and wall thickness. Hot or cold, rusty or clean material, requires different cutting settings. For fine tuning the operator can overrule the gas presets by the dials on the machine interface.

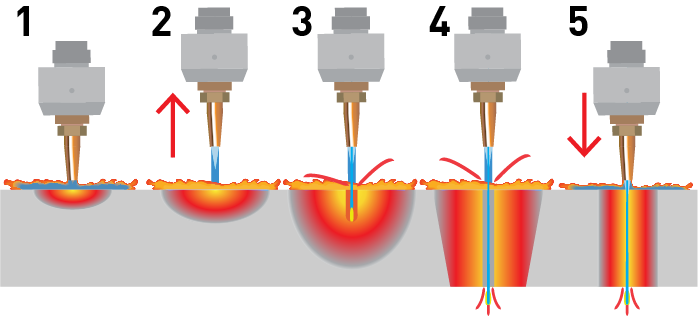

Including pierce assist cutting to get the piercing right each time

The pierce assist function guides the operator to achieve the best combination of torch position, gas mixture and pressure of the pre-heater and the cutting oxygen.

When thick-walled material is pre-heated for too long, the input of oxygen will cause a lot of spatters and create a large crater with an excess of liquid slag. This spatter will stick to the nozzle and negatively affect the gas flow and thus cutting process.

Insufficient pre-heating will mean that the full wall thickness has not reached the ignition temperature to maintain the exothermic process. The process will stop halfway, and the operator will have to try again at another starting point resulting in damage to the part and will cause more time spent on grinding and welding.

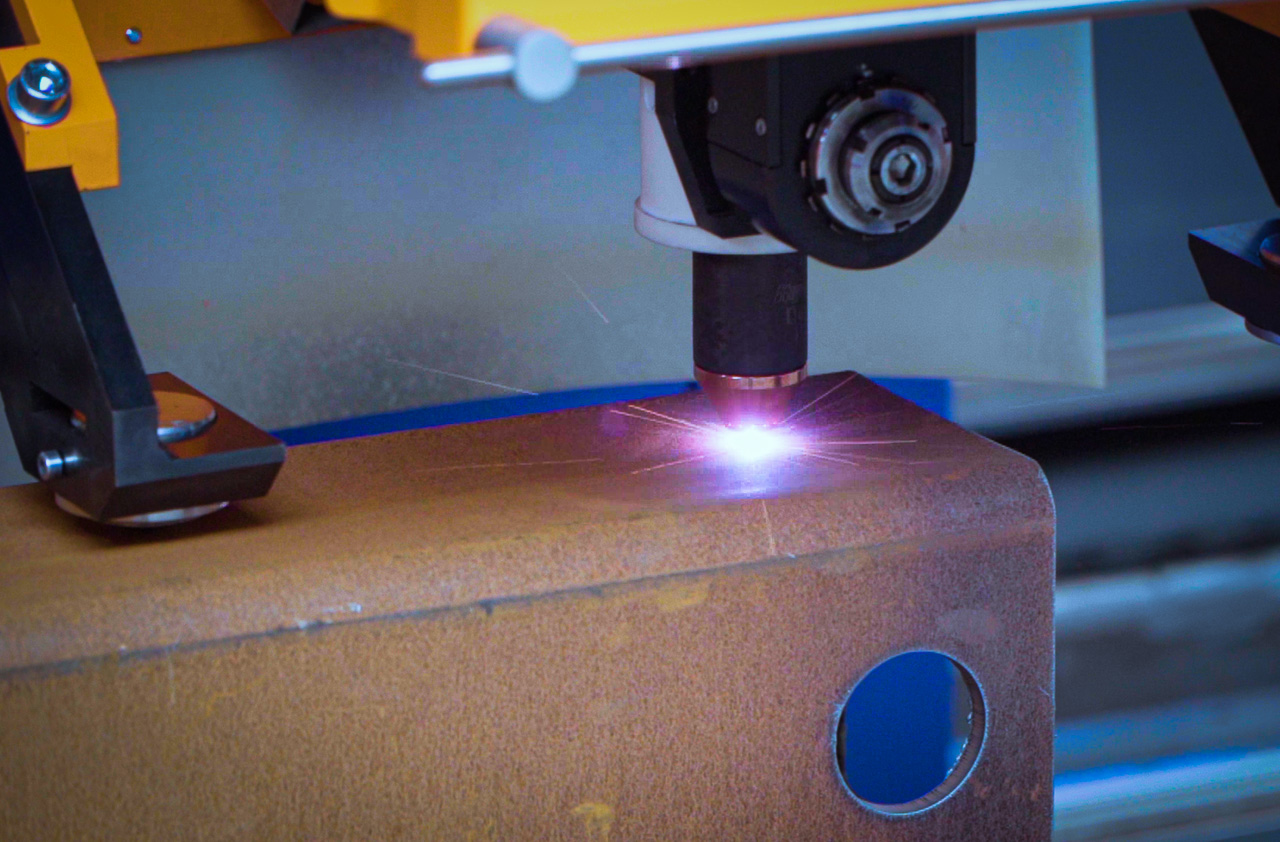

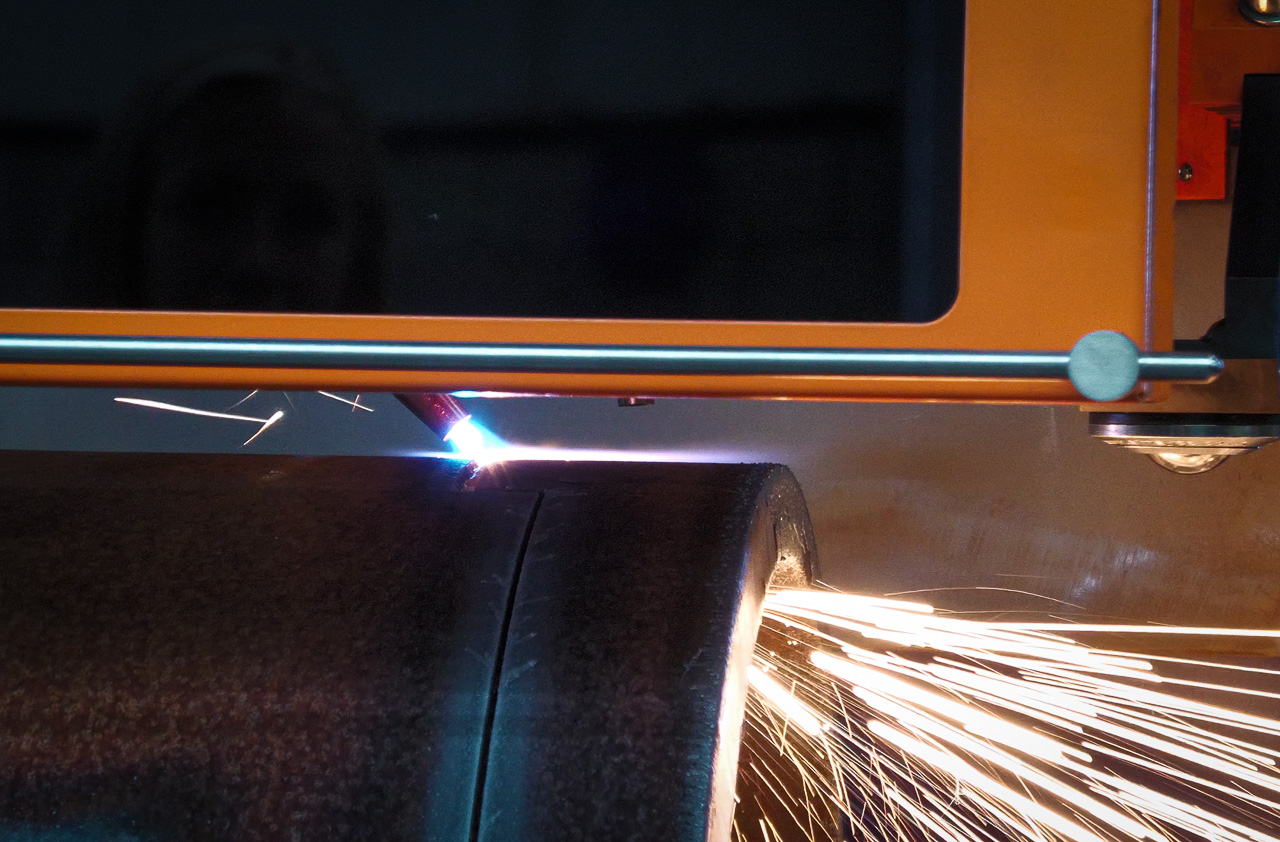

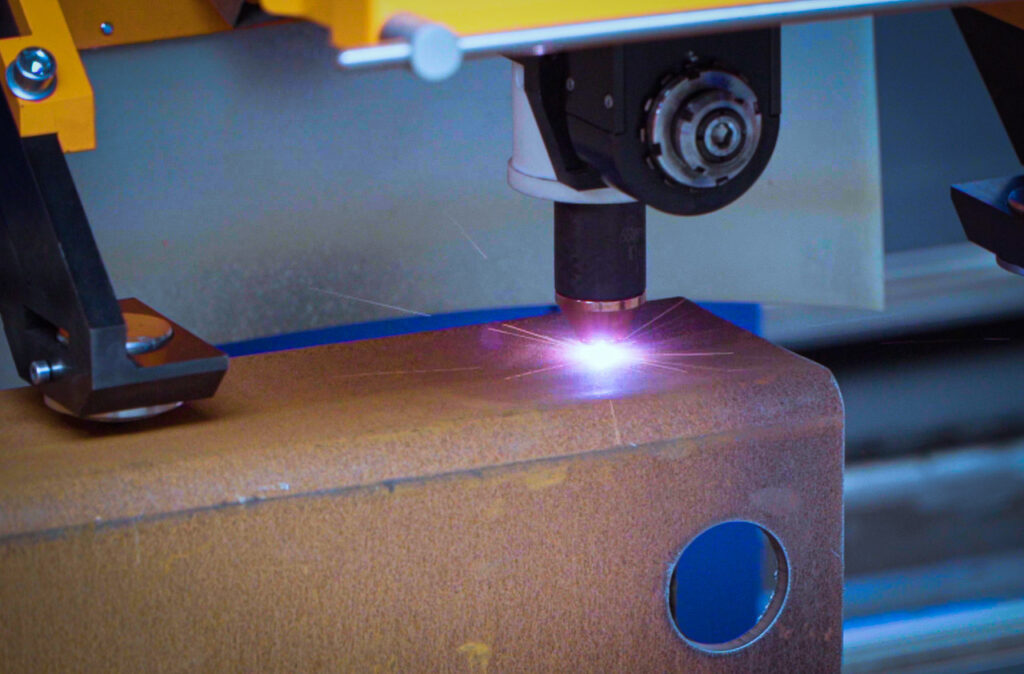

or with Plasma

HGG has distinguished itself as a pioneer in CNC plasma cutting. Since 1994, HGG has supplied over 500 3D profiling machines with plasma cutting technology worldwide and keeps innovating with plasma cutting technology to stay on top of the latest developments.

HGG offers unique features that further improve the quality of plasma cutting by compensating for plasma characteristics and/or prolonging consumable lifetime.

We support both Kjellberg and Hypertherm plasma sources. Two well experienced and industry leading choices.

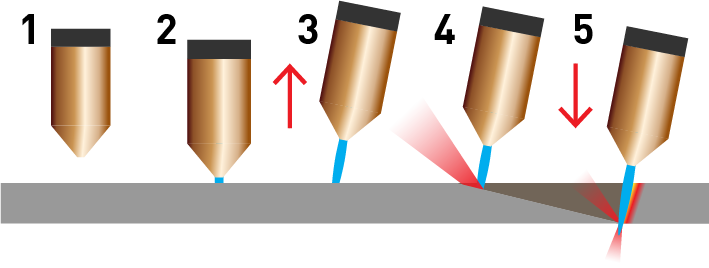

With Angled Piercing technology to protect your plasma consumables

Plasma consumables can become costly if you need to replace them regularly. The angled piercing routine keeps the nozzle and other consumables out of harm’s way, saving you time and money.

Eliminate Material waste with jaws suited to your needs

The chuck and jaw mounts, designed by HGG, are milled from a solid block of steel, ensuring high material consistency and strength. This contributes to excellent accuracy.

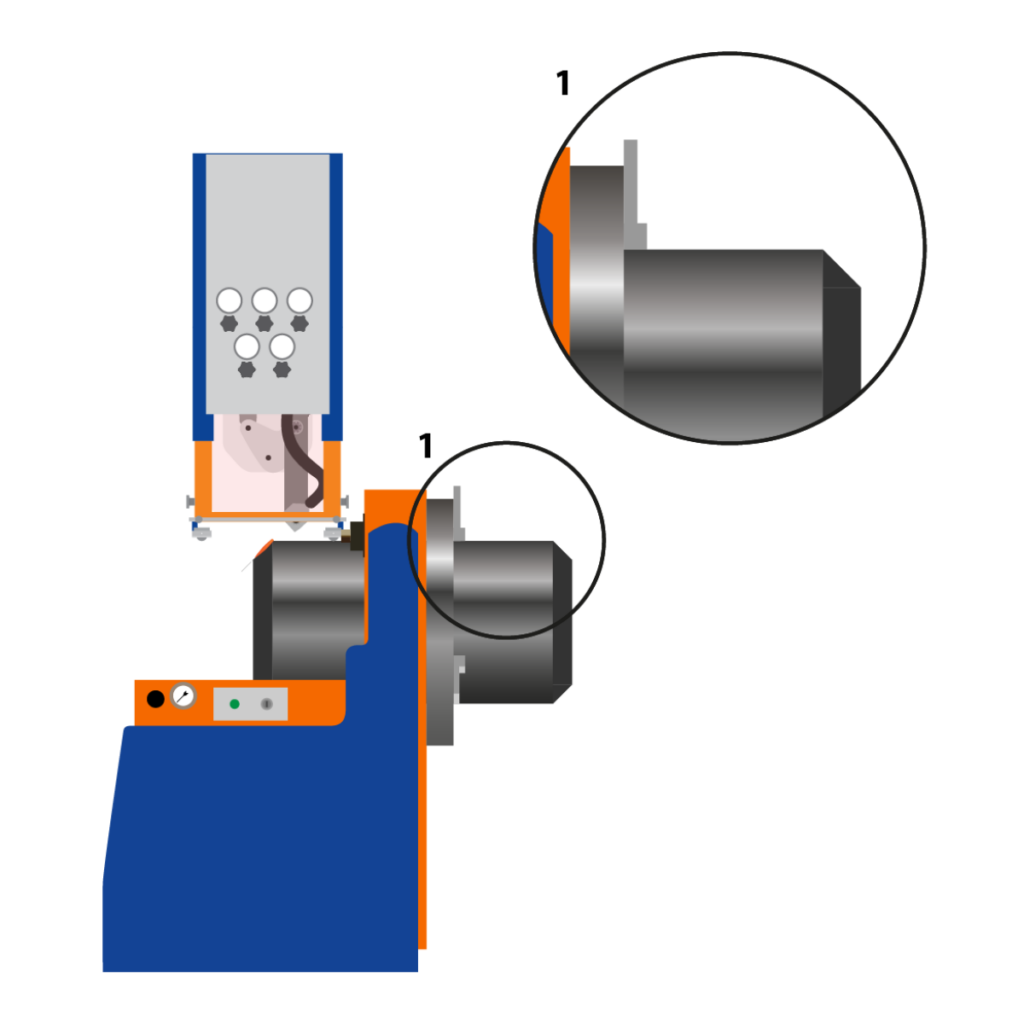

Standard Jaws

The hole through the center of the chuck allows for cutting on both sides of the main drive, depending on the chuck’s maximum hole diameter. The ‘Standard Jaws’ are ideal for this purpose.

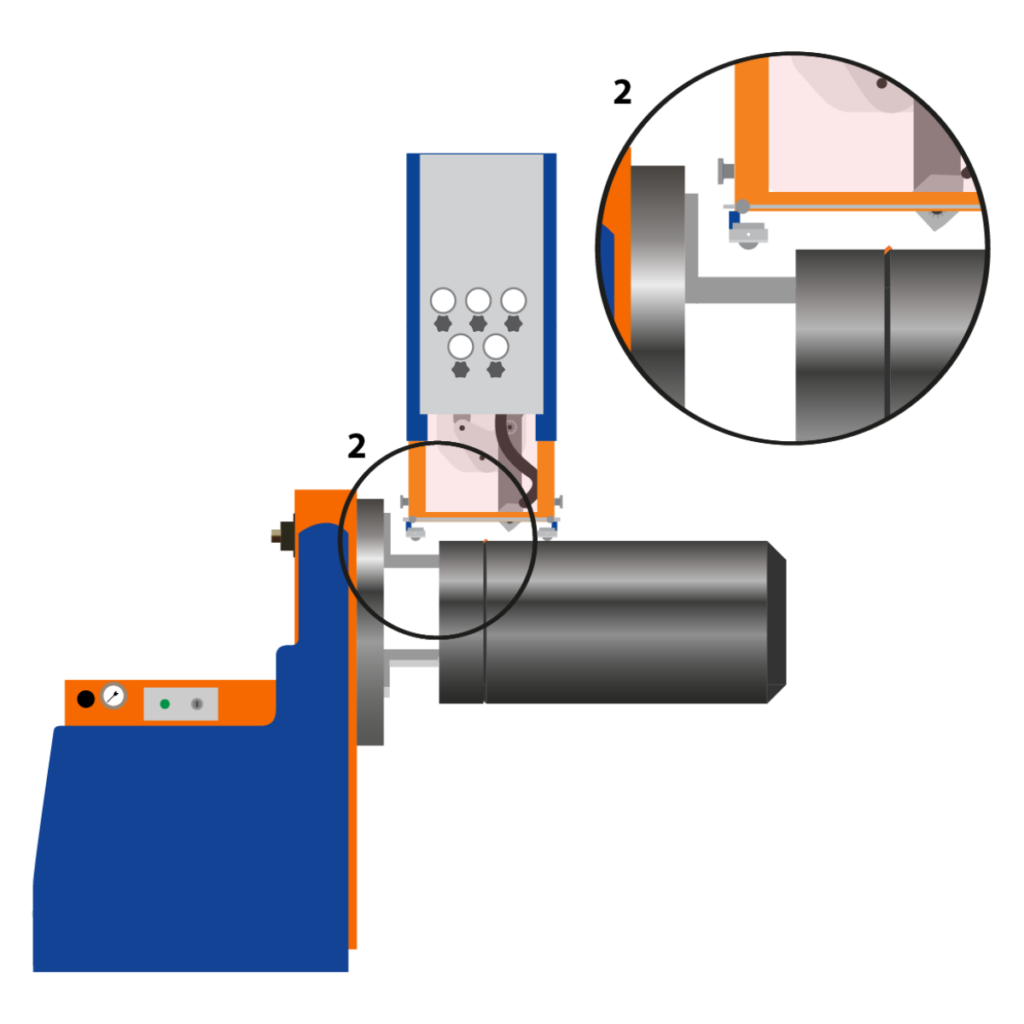

Long Jaws

The ‘Long Jaws’ cut on the front side of the main drive, saving scrap length, while ‘Standard Jaws’ require extra pipe length to avoid collisions with the main drive. ‘Long Jaws’ solve this by clamping the pipe further from the main drive.

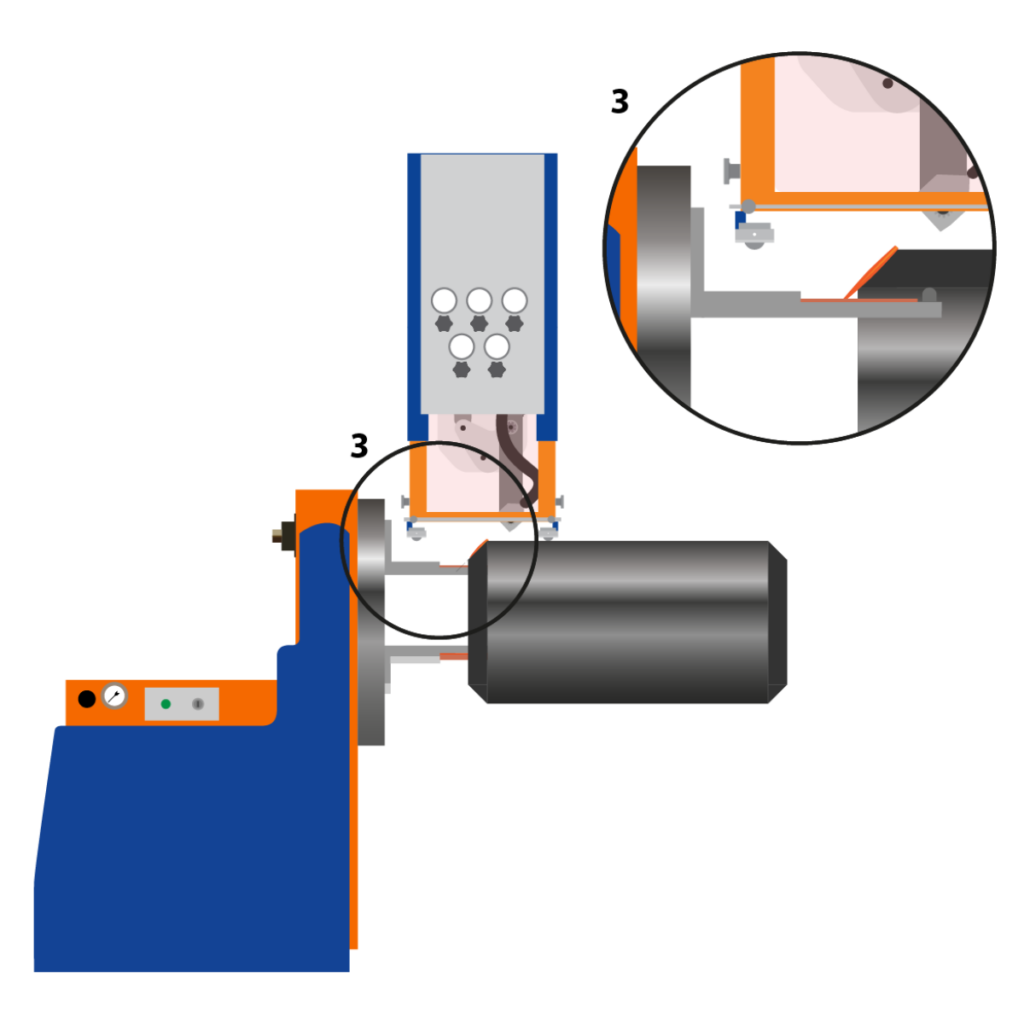

Zero Scrap Jaws

‘Zero Scrap Jaws’ eliminate the need for extra material. These jaws, protected by copper plates, are perfect for cutting straight chamfers with both X/K bevels and single cuts.

Featured Case Study

Before we bought the MPC some jobs were impossible to do at all. Now we can make very precise fits, which significantly reduces manual work.

Tomasz Luba - Mostostal Pomorze SA