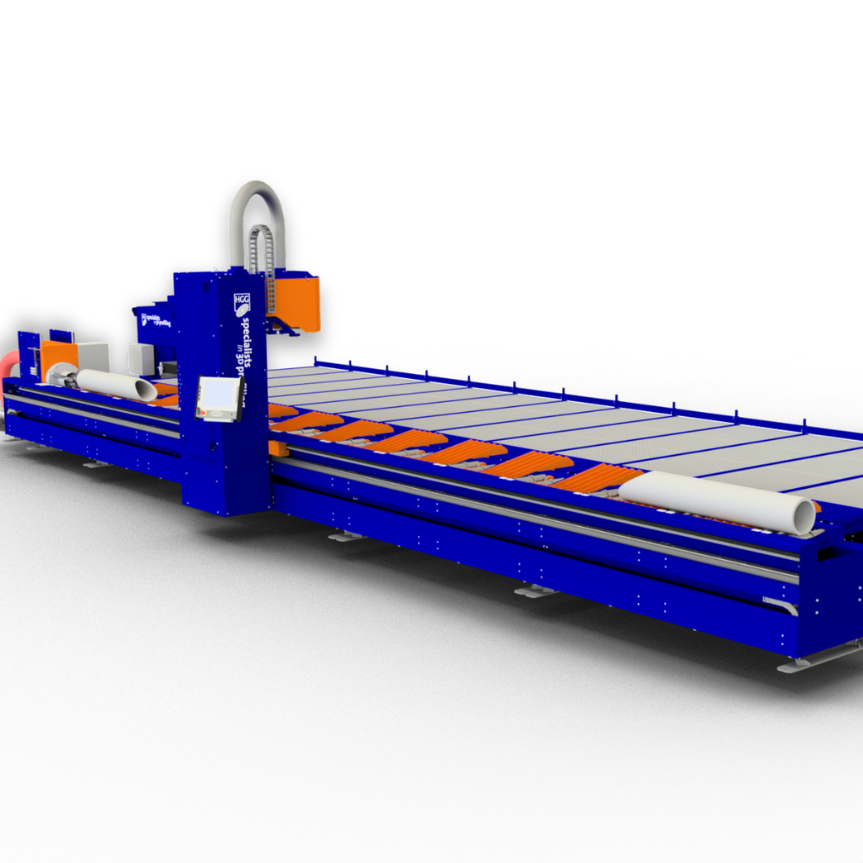

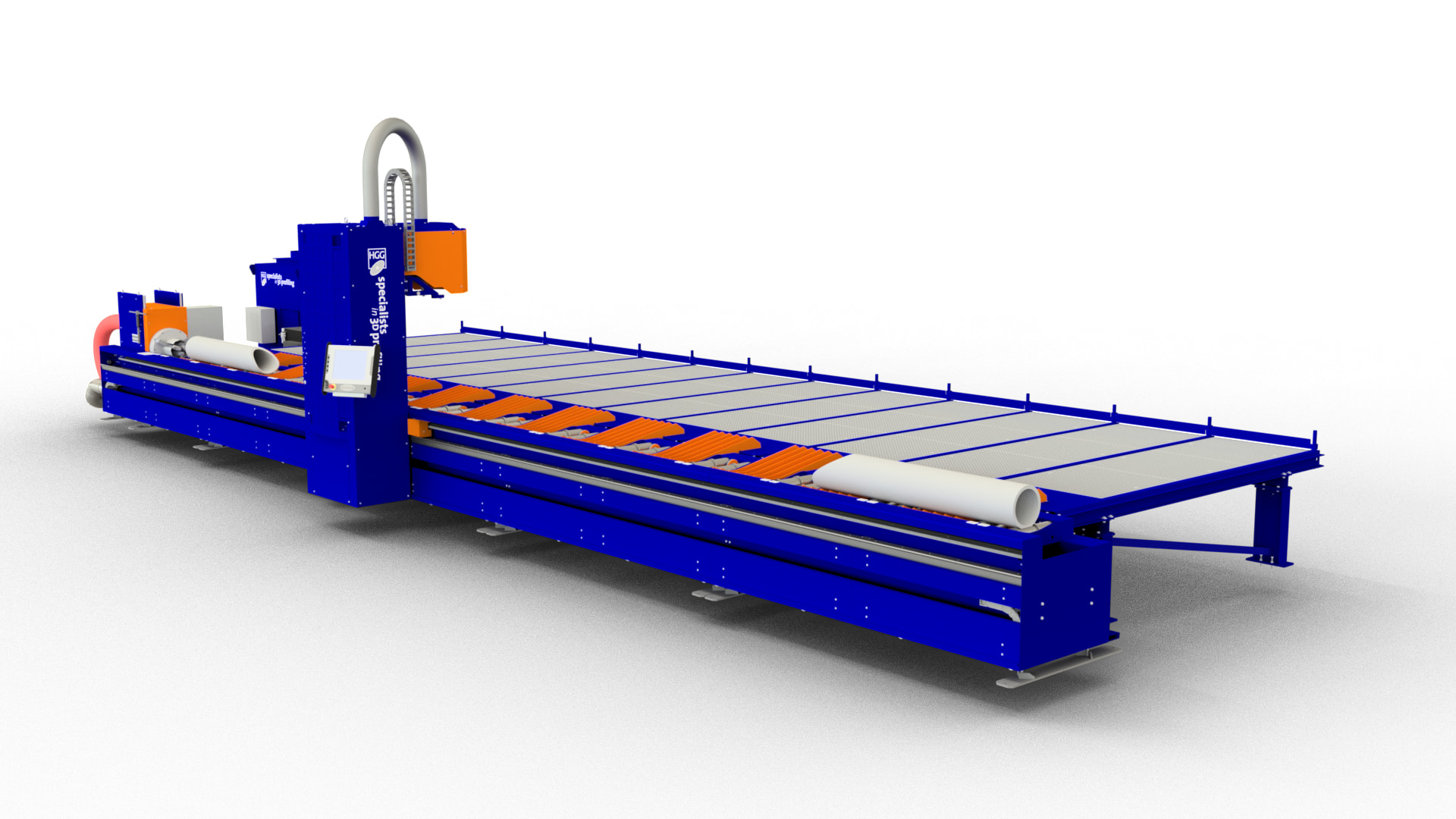

Product Tour ProCutter 900 RB

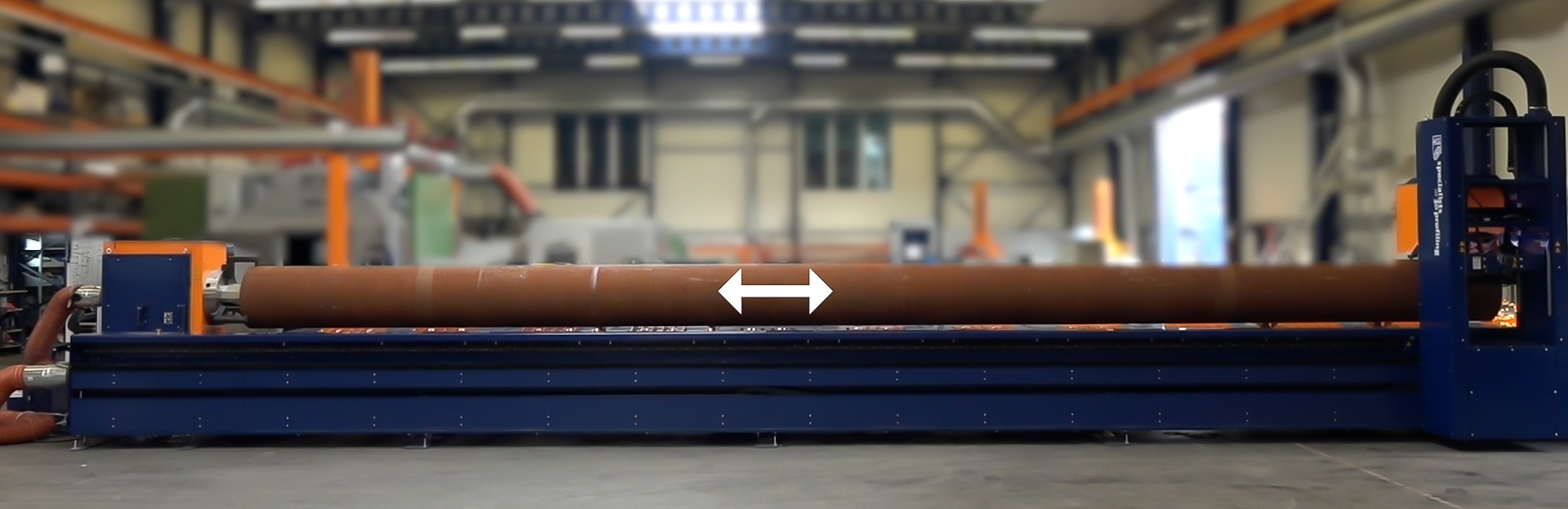

Heavy-duty Pipe Profiler with a roller bed outfeed.

WATCH VIDEO

Compact and Streamlined Productivity

Developed in collaboration with a mechanical contractor, the ProCutter 900 RB is designed for high-speed pipe processing, quickly moving pipes through the shop to feed the welders. It automates the transfer of pipes from outdoor storage to the cutting area, where they are clamped securely in the chuck. Once the pipe is fully cut, it is automatically unloaded onto a storing surface for operators to collect, streamlining the workflow and enhancing efficiency.

Specifications

Profile & Dimensions

- Profile

- Minimum

- Maximum

| 48 mm | 914 mm |

| 2 “ | 36 “ |

Additional Specifications

- Plasma cutting

- Plasma marking with cutting torch

- Plasma powersource: Hypertherm or Kjellberg

- Maximum Cutting Angle: 45 degrees

- CAD Connection

Discover the possibilities of the ProCutter 900 RB

Process Piping

The ProCutter is the ideal machine for piping, capable of cutting chamfers, saddles, and holes, all ready for fitting and welding.

Line and Text Marking

Marking reference lines to significantly reduce fit-up time. Text marking can also be used for tracking and tracing cut parts.

Hole Cutting

The ProCutter can cut holes for both structural and process piping purposes.

Special Weld Preparations

The ProCutter supports special weld preparations for structural purposes to simplify the welding without compromising on strength.

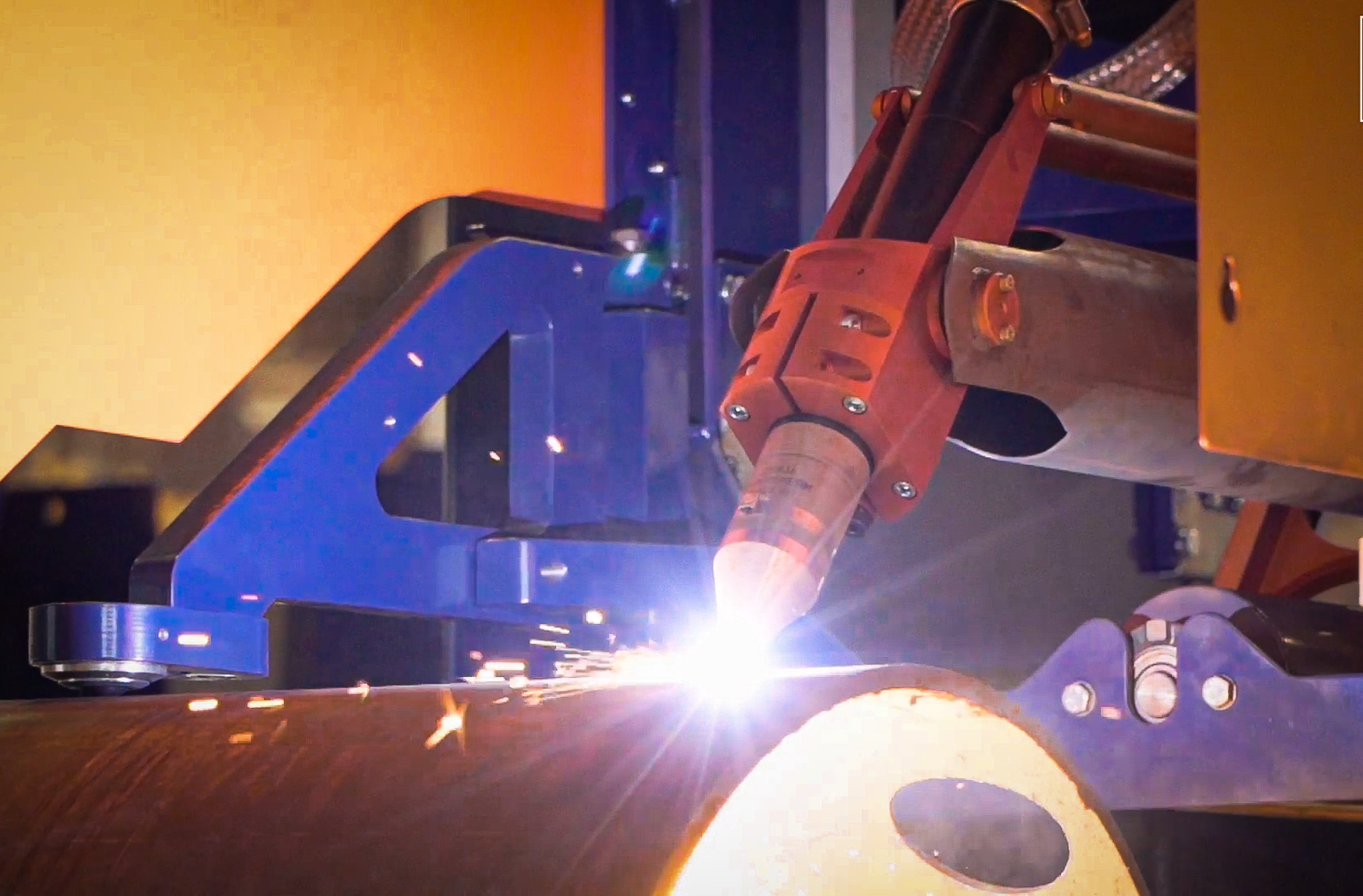

High speed pantograph cutting head

The ProCutter 900 RB is built for heavy-duty jobs. A standout feature of this machine is its pantograph cutting head, which allows for 360-degree pivoting and 45-degree beveling giving you full freedom to create.

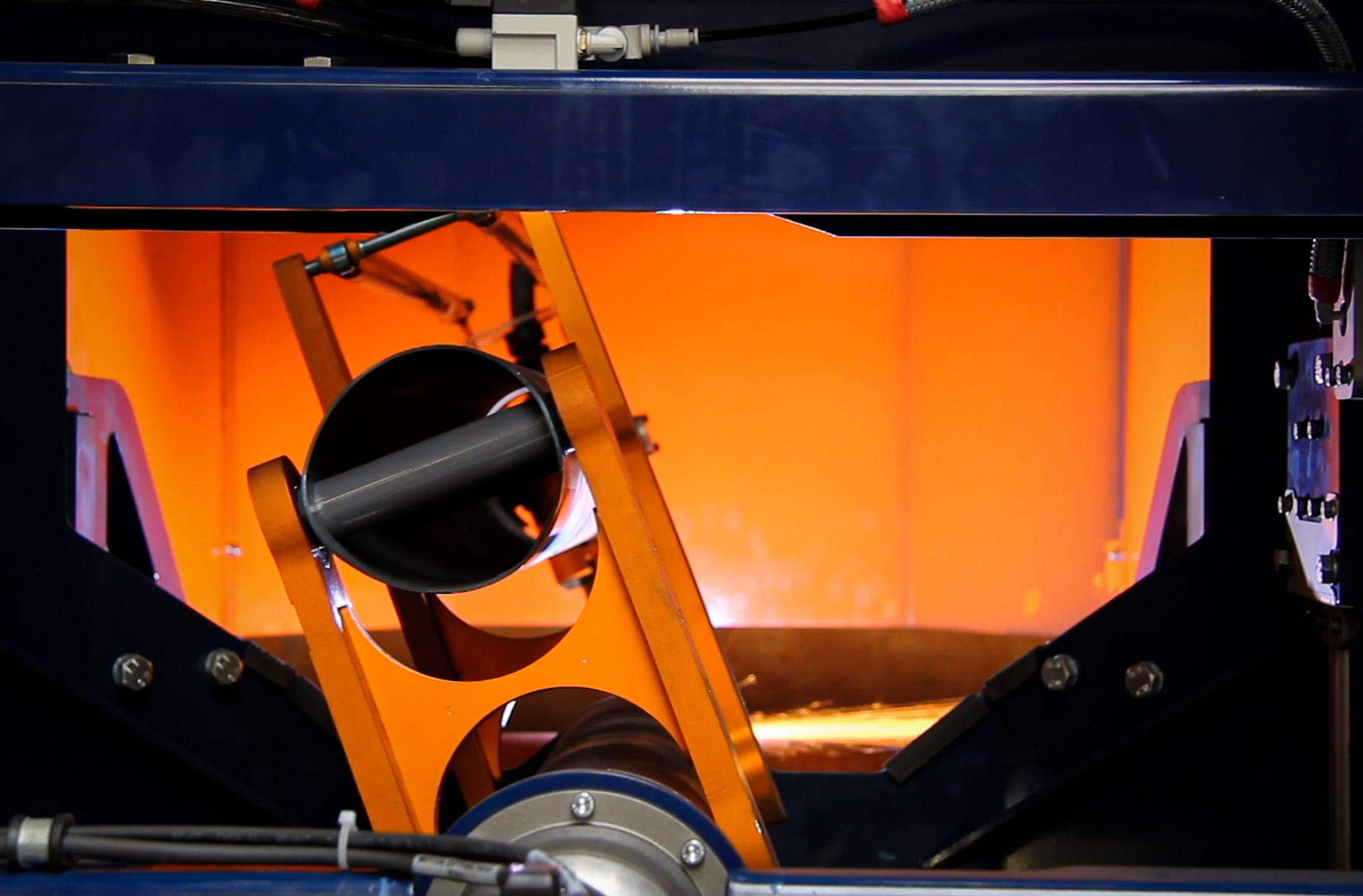

Independent lifting bogies minimize strain on both the machine and the pipe

The lifting bogies in the rollerbed can move up and down independent of one another, so that we’re not putting all of the wheels up at the same time, creating stress on the pipe and machine.

Efficient unloading with automatic kick-out levers

Once your parts are cut and ready for unloading, the kick-out levers tilt to transfer the pipes onto an unloading surface, where they are stored ready to be taken to the welding station.

The open design of the kick-out levers allows scrap material and slag to fall through, preventing blockages on the outfeed and ensuring smooth operation.

Enhanced machine safety with automatic Pipe Detection levers

The ProCutter 900 RB is equipped with automatic pipe detection levers that slow down the pipe as it approaches the chuck, ensuring enhanced operational safety and precision.

Smart creep compensation to maximize cutting accuracy

Featured Case Study

'Growth requires change, and the HGG Machine a really big part of that journey.'

Kim Bassett, CEO and Chairwoman of the Board