HGG Expands Global Reach with New Sales Appointments

We’re thrilled to welcome Benjamin Dunn and Gijs Beerepoot as the newest members of our global sales organization. With their strong industry backgrounds and customer-driven approach, Ben and Gijs bring valuable experience and fresh energy to our team. Their appointments reinforces HGG’s commitment to delivering world-class cutting solutions and dedicated support to customers worldwide.

Innovation project PARADAIM launched!

The PARADAIM innovation project is getting underway. Together with partners and knowledge institutions, we are developing an AI-supported digital design process for faster and smarter mechanical engineering.

HGG CCO Wiebe Wiersma Interviewed by Manufacturing Today

The recent launch of our APC was a good reason for Manufacturing Today to catch up with HGG’s Chief Commercial Officer, Wiebe Wiersma who explained the ideas and technology behind the APC.

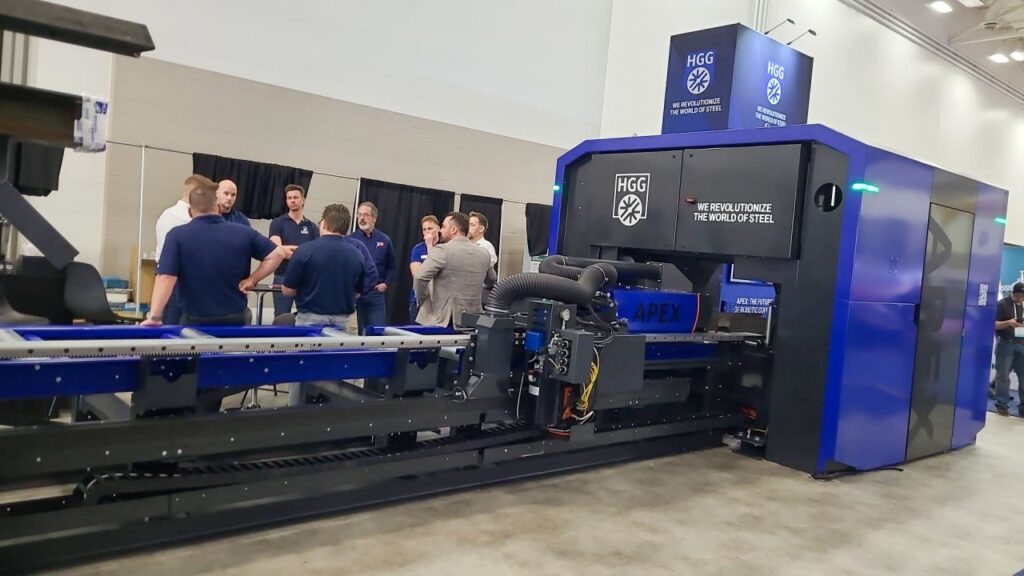

New benchmark in Steel Fabrication: HGG Unveils APC at NASCC 2025

Earlier this month, HGG was back as an exhibitor at NASCC – The Steel Conference in Kentucky — one of the most influential events in the structural steel industry in the USA.

CNC Plasma Cutting Streamlines Helical-Pile Fabrication at Sealevel Construction

Metalforming Magazine features Sealevel Construction’s successfull transformation of their pipe processing using HGG’s CNC solutions.

Discover HGG 2025: Exhibits & Events

This 2025 our team is travelling the world to events & exhibits near you! We love to share you the overview of where you can meet our team of 3D profiling experts.

ProCAM ProCommand: Optimizing production with Powerfab and StruMIS

Boost production efficiency with seamless automation! The integration of ProCAM with Powerfab or StruMIS eliminates manual exports, automates data exchange, and optimizes material usage with intelligent nesting. ProCommand ensures real-time status tracking, improving workflow visibility and reducing delays. Experience a fully automated, transparent process from part creation to completion.

Explaining HGG Through the Eyes of a Child

Explaining what HGG does to a child might seem tricky, but sometimes the simplest explanations come from kids themselves! In this video, Fenna shares her perspective in her own words, making complex concepts about precision steel profiling easy to understand