Alternative Ways to Break Edges on Beams

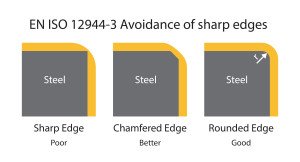

Creating a barrier against corrosion is essential for extending the lifetime of steel structures. Edge breaking is therefore applied for improving the surfaces for coating coverage and ultimately corrosion protection. High surface tension of liquid coating pulls the film away on sharp edges resulting in an insufficient coating thickness.

Coating failure makes an edge more susceptible to corrosion. Protective paints and other coatings cannot adhere to sharp material edges. To ensure an even and complete coating on the surface of edges on beams, T-bars and flat-bars, those edges need to be at first rounded. There are two common ways fabricators use for edge breaking of beams and bars: chamfering and rolling. The latter can be achieved in three ways: grinding, milling and edge rounding by rolling performed by means of automated machinery.

Edge Breaking by Chamfering versus Edge Rounding

The disadvantage of chamfering is the creation of new edges which still creates the same dispel effect of liquid coating by the high surface tension.

This makes edge rounding a preferred process compared to chamfering. The most common edge rounding techniques in practice are machining operations like grinding and milling. Both power tools and semiautomatic machinery are available to round edges by machining and are most typically found in practice.

We will have a closer look at the three alternative techniques of achieving the latter;

- Grinding

- Milling

- Rolling

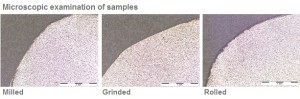

Milling

The milled sample on the picture below shows the result of edge rounding by semi-automatic machinery. It is very hard to guide the mill along the edge and a mill is not willing to forgive any positioning deviation. This results in unwanted rut forming. As you can see the edges are rounded but a bit chamfered and not fully rounded. The picture also shows an indentation. This process does not guarantee a constant coating thickness.

Grinding

The grinded sample on the picture shows the result of edge rounding by semi-automatic machinery. The edges are rounded but a bit chamfered and not fully rounded. This chamfered surface structure is the result of multiple grinding movements along the edge. Grinding can create a rounded edge based on multiple chamfers. This explains why the edge is not completely rounded. That is why grinding does not guarantee a constant coating thickness.

Rolling

The third alternative is rolling. A hardened rolling mill with a round shape presses on the edge to deform the mild steel which creates a perfectly rounded edges on the material. The roll guides itself and is willing to forgive any positioning deviation. This fast, noiseless and dust free technique has only one disadvantage. The material hardness increases slightly at the edge where the force is applied. Research is needed to check if the increased hardness interferes with the material standards.

Edge Rounding is an Alternative Way for Edge Breaking of Beams

Edge breaking by rolling has long been thought of as a process which deforms the material and so can result in micro cracks and hardening and has thus been often avoided. It is believed that the process can affect the material properties, which would then not be able to meet the standards and codes. However, in case of edge breaking of the surface edges only, the deformed volume is very little and within the international standards.

- Download the full article: Edge Breaking Alternative; Edge Rounding

Stay up-to-date?

Do you want to have access to the newest articles, be the first to hear about our new products and get updates on industry events?