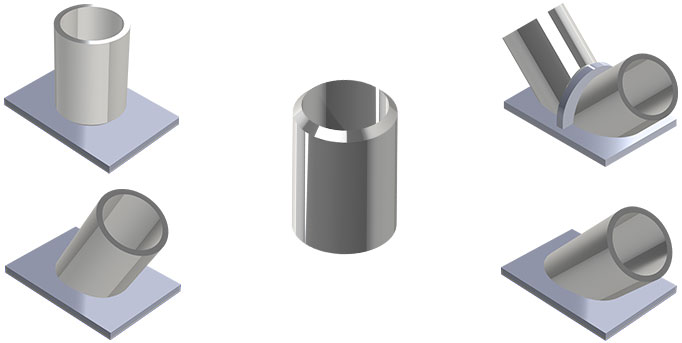

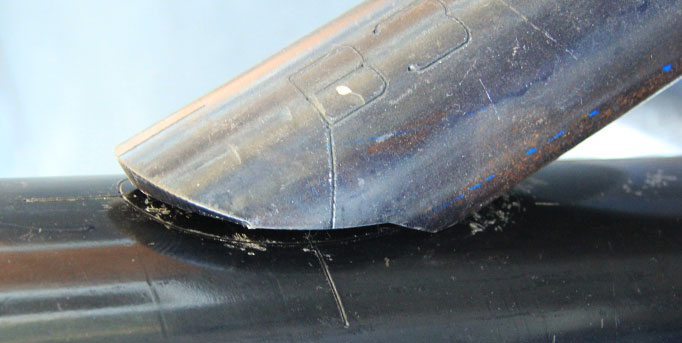

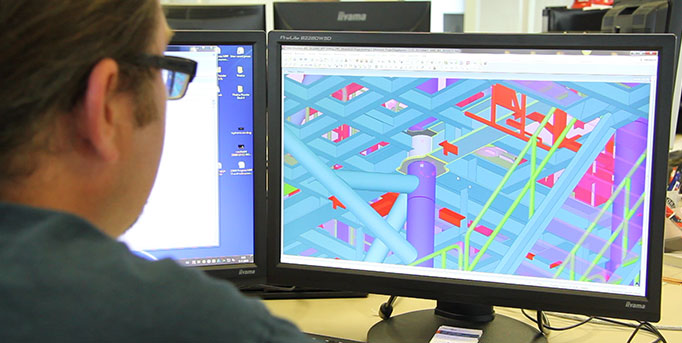

Chamfer Profiling Shapes are applied for plate connections or to connect pipe ends

Chamfer: For perpendicular or slightly sloped pipe to plate connections.

Chamfer PJP: A plasma optimized shape for angled pipe to plate connections and rapid cutting.

Chamfer Offshore: A pipe to plate connection with a slope less than 45° in accordance with AWS for offshore industries.

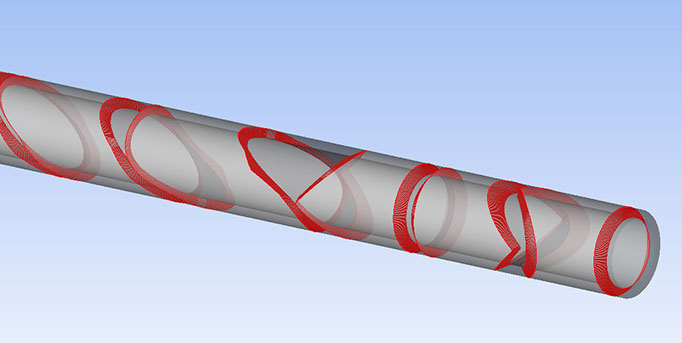

Chamfer X-bevel: To reduce welding volume or to apply a tapering.